GE Multilin

T35 Transformer Protection System

B-1

APPENDIX B

B.1 MODBUS RTU PROTOCOL

B

APPENDIX B MODBUS COMMUNICATIONSB.1MODBUS RTU PROTOCOL

B.1.1 INTRODUCTION

The UR-series relays support a number of communications protocols to allow connection to equipment such as personal

computers, Remote Terminal Units (RTUs), SCADA masters, and programmable logic controllers. The Modicon Modbus

protocol is the most basic protocol supported by the UR. Modbus RTU is available via the RS232 and RS485 serial links,

and Modbus TCP/IP is available over Ethernet. The following description is intended primarily for users who want to

develop their own master communication drivers. Note that:

•

The UR always acts as a slave device, meaning that it never initiates communications; it only listens and responds to

requests issued by a master computer.

•

A subset of the Modbus RTU and Modbus TCP/IP protocol format is supported that allows extensive monitoring, pro-

gramming, and control functions using read and write register commands.

B.1.2 PHYSICAL LAYER

The Modbus RTU protocol is hardware-independent so that the physical layer can be any of a variety of standard hardware

configurations including RS232 and RS485. The relay includes a faceplate (front panel) RS232 port and rear terminal

RS485 port. Data flow is half-duplex in all configurations. See chapter 3 for details on communications wiring.

Each data byte is transmitted in an asynchronous format consisting of 1 start bit, 8 data bits, 1 stop bit, and possibly 1 parity

bit. This produces a 10 or 11 bit data frame. This can be important for transmission through modems at high bit rates (11 bit

data frames are not supported by many modems at baud rates greater than 300).

The faceplate RS232 port is for local use and is fixed at 19200 bit/s baud and even parity. The rear terminal RS485 port can

be set for baud rates of 300, 1200, 2400, 4800, 9600, 14400, 19200, 28800, 33600, 38400, 57600, or 115200 bps, and

even, odd, and no parity options are available. See the

Communications

section of chapter 5 for further details.

The Modbus TCP/IP protocol is available on each of the rear Ethernet ports. Depending on the relay's order code, these

ports can be 10/100Base-TX or 100Base-FX.

B.1.3 DATA LINK LAYER

Modbus RTU communications takes place in packets which are groups of asynchronously framed byte data. The master

transmits a packet to the slave and the slave responds with a packet. The following describes general format for both trans-

mit and receive packets. For exact details on packet formatting, refer to subsequent sections describing each function

code.

•

SLAVE ADDRESS:

This is the address of the slave device that is intended to receive the packet sent by the master

and to perform the desired action. Each slave device on a communications bus must have a unique address to prevent

bus contention. All of the relay’s ports have the same address which is programmable from 1 to 254; see chapter 5 for

details. Only the addressed slave will respond to a packet that starts with its address. Note that the faceplate port is an

exception to this rule; it will act on a message containing any slave address.

A master transmit packet with slave address 0 indicates a broadcast command. All slaves on the communication link

take action based on the packet, but none respond to the master.

•

FUNCTION CODE:

This is one of the supported functions codes of the unit which tells the slave what action to per-

form. See the

Supported Function Codes

section for complete details. An exception response from the slave is indi-

cated by setting the high order bit of the function code in the response packet. See the

Exception Responses

section

for further details.

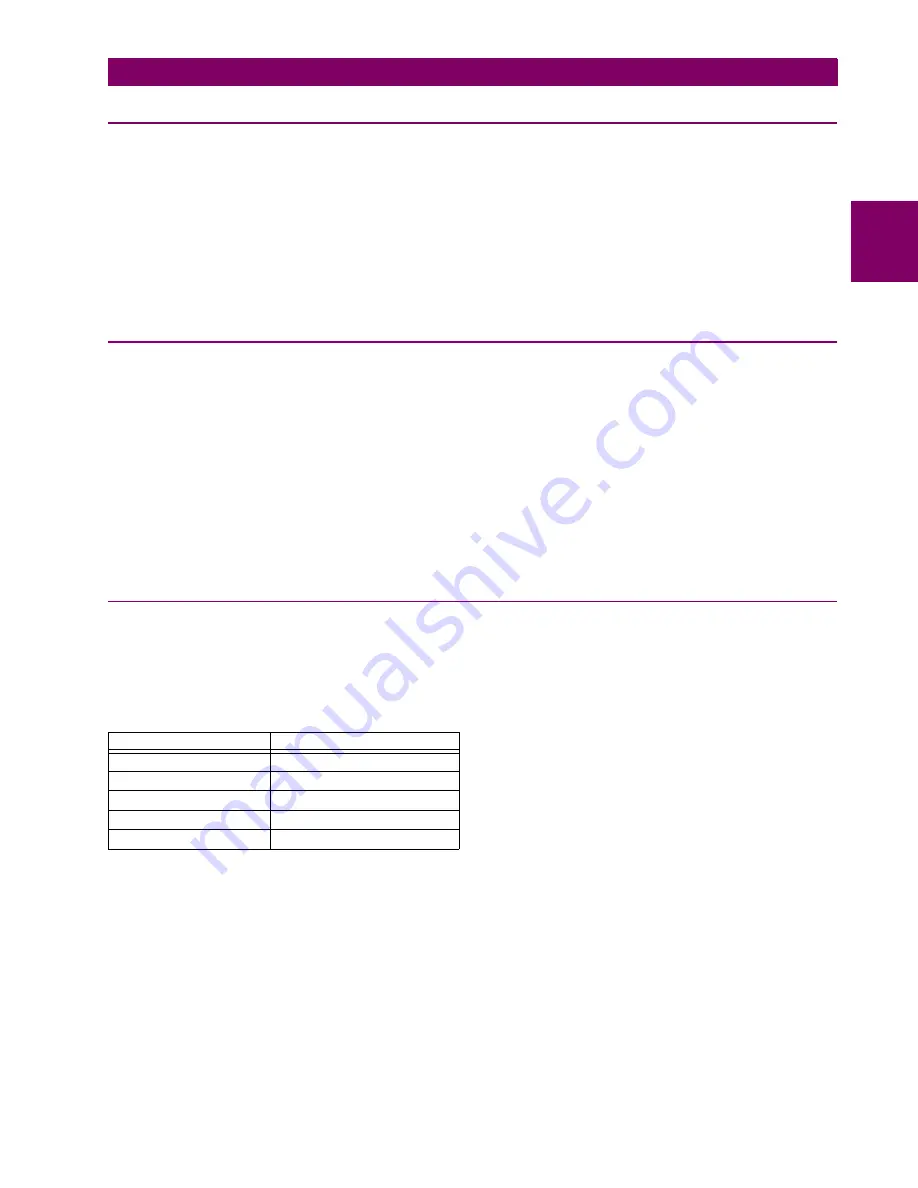

Table B–1: MODBUS RTU PACKET FORMAT

DESCRIPTION

SIZE

SLAVE ADDRESS

1 byte

FUNCTION CODE

1 byte

DATA

N

bytes

CRC

2 bytes

DEAD TIME

3.5 bytes transmission time

Содержание T35 UR Series

Страница 10: ...x T35 Transformer Protection System GE Multilin TABLE OF CONTENTS ...

Страница 48: ...2 18 T35 Transformer Protection System GE Multilin 2 2 SPECIFICATIONS 2 PRODUCT DESCRIPTION 2 ...

Страница 314: ...5 192 T35 Transformer Protection System GE Multilin 5 10 TESTING 5 SETTINGS 5 ...

Страница 338: ...6 24 T35 Transformer Protection System GE Multilin 6 5 PRODUCT INFORMATION 6 ACTUAL VALUES 6 ...

Страница 350: ...7 12 T35 Transformer Protection System GE Multilin 7 2 TARGETS 7 COMMANDS AND TARGETS 7 ...

Страница 366: ...8 16 T35 Transformer Protection System GE Multilin 8 2 CYBERSENTRY 8 SECURITY 8 ...

Страница 382: ...9 16 T35 Transformer Protection System GE Multilin 9 5 COMMISSIONING TEST TABLES 9 COMMISSIONING 9 ...

Страница 406: ...A 14 T35 Transformer Protection System GE Multilin A 1 PARAMETER LISTS APPENDIX A A ...

Страница 540: ...D 10 T35 Transformer Protection System GE Multilin D 1 IEC 60870 5 104 PROTOCOL APPENDIX D D ...

Страница 552: ...E 12 T35 Transformer Protection System GE Multilin E 2 DNP POINT LISTS APPENDIX E E ...

Страница 560: ...F 8 T35 Transformer Protection System GE Multilin F 3 WARRANTY APPENDIX F F ...