25

MAINTENANCE

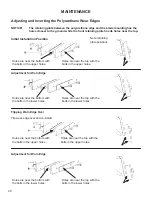

Inverting Front Wear Edges

NOTICE!

All nuts and bolts must be installed using proper torque specifications (refer to Bolt

Torque Specifications).

1. Park prime mover on a firm, level surface with blade properly attached.

2. Lower the blades cutting edge onto a sturdy wood or metal blocking positioned under the pivoting

assembly, to safely hold the wear edge 6 to 8 inches above the level surface.

3. Place primer mover in “Park” and engage parking brake.

4. Remove and retain all nuts and bolts but the ones at each end of the wear edge.

5. Support one end of the wear edge, remove the nut and bolt, then lower it to the level surface.

6. Support the other end, remove the nut and bolt and lower to the level surface.

7. Flip the edge over so the worn side is facing up.

8. Support one end of the wear edge and re-install nut and bolt.

9. Support the other end and re-install nut and bolt

10. Re-install all nuts and bolts.

11. Repeat steps 4-10 for other wear edge.

12. Center rubber wear edge and plates must also be inverted with wear edges.

NOTICE!

When installing nuts and bolts on center rubber wear edge, DO NOT tighten to

specified torque. Tighten until the retaining plate has slightly compressed the rubber.

Front Wear Edges

Center Wear Edges

Содержание V-Snow Blade

Страница 2: ...2 Notes...

Страница 17: ...17 OPERATION figure 2 figure 3 Level Scoop Position Shown...

Страница 24: ...24 MAINTENANCE RECORD Date Maintenance Procedure Performed Performed by Comments...

Страница 34: ...34 HYDRAULIC ELECTRIC MANIFOLD SCHEMATIC...

Страница 35: ...35 HYDRAULIC MANIFOLD SCHEMATIC...

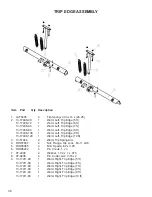

Страница 36: ...36 MOLDBOARD ASSEMBLY...

Страница 41: ...41 NOTES...