23

MAINTENANCE SCHEDULE

Maintenance Schedule

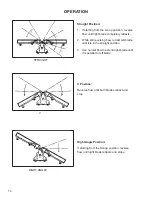

Procedure

Before

Each Use

After

Each Use

Fittings/Hoses, Hydraulic

- Check for leaks/Tighten

Check for damage

Fittings, Zerk

- Grease (See lubrication points)

Oil, Hydraulic

- Check level

Hardware

- Check for tightness

Oil Cleanliness Requirements

NOTICE!

All hydraulic fluid shall be filtered before use in any FFC product to obtain the ISO

cleanliness standard of 17-14 or better, unless explicitly specified otherwise.

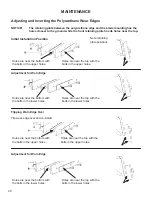

Lubrication Points

The following grease fittings should be greased before each use. See figure for locations.

1. Cylinders (2 fittings per cylinder)

2. Center Pin (2 fittings)

3. Ball Joint (B-Design, 1 fitting)

Содержание V-Snow Blade

Страница 2: ...2 Notes...

Страница 17: ...17 OPERATION figure 2 figure 3 Level Scoop Position Shown...

Страница 24: ...24 MAINTENANCE RECORD Date Maintenance Procedure Performed Performed by Comments...

Страница 34: ...34 HYDRAULIC ELECTRIC MANIFOLD SCHEMATIC...

Страница 35: ...35 HYDRAULIC MANIFOLD SCHEMATIC...

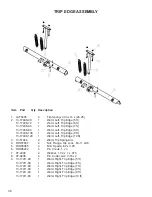

Страница 36: ...36 MOLDBOARD ASSEMBLY...

Страница 41: ...41 NOTES...