49

!

!

Edgebander

G 330 / G 360 / G 380

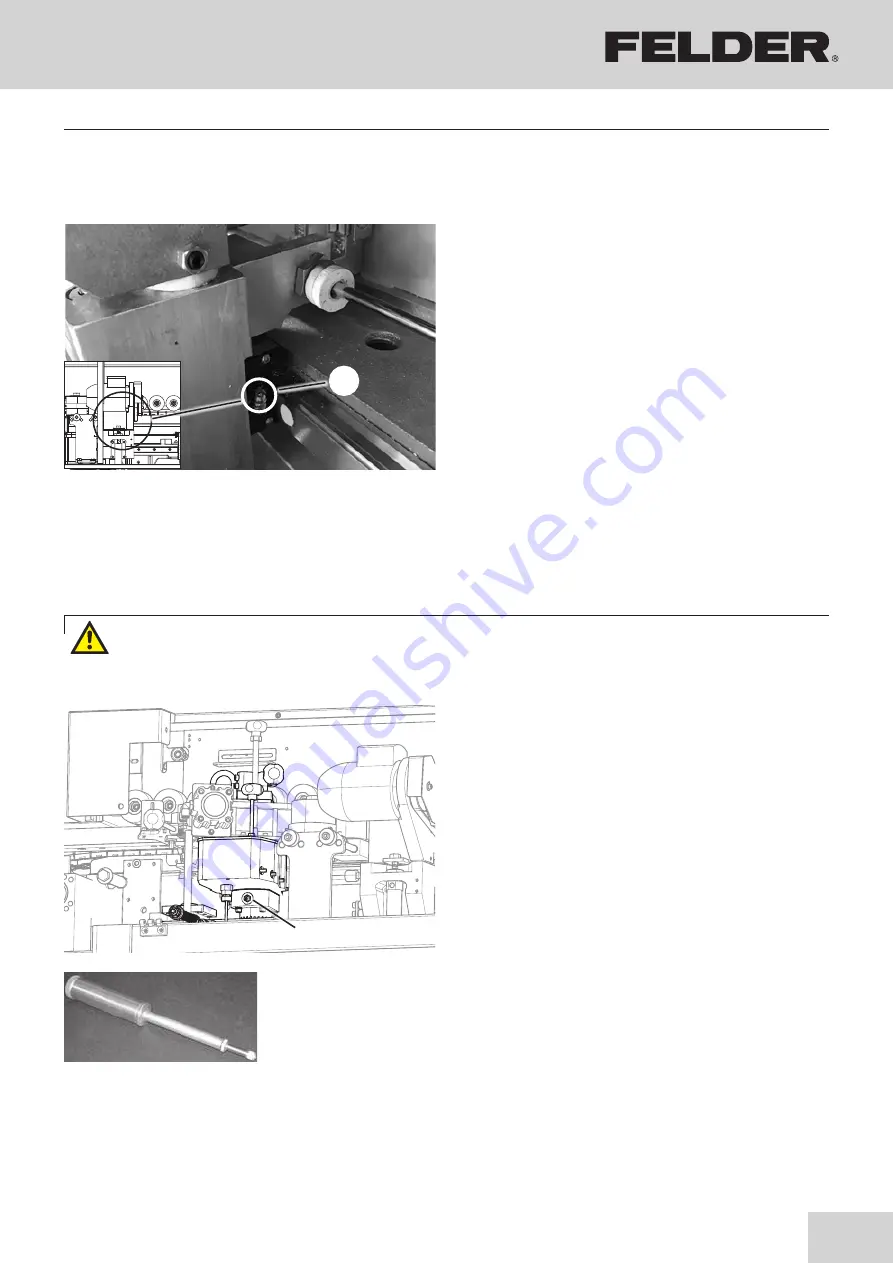

10.3.1 Lubrication -

End trimming unit

Maintenance/Service

Switch the machine on and let it warm up to its ope-

rating temperature.

Switch the machine off and ensure that it cannot be

switched on again.

Place the pressure grease gun onto the nipple and

insert 2 to 3 squirts.

Switch the machine on and let it warm up to its

operating temperature.

!

Lubricant nipple

Fig. 10-3 : Lubrication End trimming unit

Lubricate the machine after every 24 to 32 operating

hours of intensive use.

Use the lubricant for high temperature bearings ARE-

XONS GC 300.

1.

Switch the machine on and let it warm up to its ope-

rating temperature.

2.

Switch the machine off and ensure that it cannot be

switched on again. Open the rear access door.

3.

Place the pressure grease gun onto the nipple and

insert 2 to 3 squirts.

4.

Switch the machine on and let it warm up to its

operating temperature.

!

Grease nipple - Glue roller

10.3.2 Lubricating the glue roller bearing

Fig. 10-4: Grease nipple - Glue roller

Warning! Risk of burns and serious injuries!

Many parts of the machine are very hot, in particular the glue pot!

Use all suitable methods of protection to prevent severe injury.