9

SECTION 3 -

SERVICING AND CONVERSION

BEFORE ATTEMPTING ANY SERVICING, TURN OFF GAS SHUT-OFF VALVE AND ELECTRICAL SUPPLY.

TAKE STEPS TO ENSURE THAT THESE CANNOT BE INADVERTENTLY TURNED ON.

AFTER ANY MAINTENANCE TASK, CHECK UNIT TO ENSURE THAT IT PERFORMS SAFELY AND

CORRECTLY AS DESCRIBED IN SECTION 2.5.

ALWAYS CHECK FOR GAS LEAKS.

3.1 GAS CONVERSION

(Natural to propane or propane to natural)

This model is suitable for field conversion.

3.2 INTEGRAL COMPONENTS

The following parts must be checked and serviced regularly:

1) Premix fan - check for dust, grease ingress.

2) Oil ingress to electrical components.

3) Flue for any blockages.

4) Visual inspection of components, gaskets and fryer pan.

3.3 ACCESS PROCEDURES

Before removal of any fryer components:

a) Ensure appliance electrical and gas supply has been shut off and cannot be accidentally turned back on.

b) Allow oil to cool before any operation that requires pan to be drained.

c) Only use parts specified by the manufacturer.

d) All components replaced MUST be fully checked after fitting to ensure safe operation.

e) A full pre-commissioning check as detailed in Section

2.5 should be carried out.

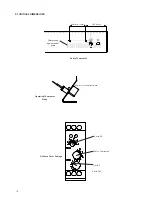

3.4 PREMIX FAN

(Preset venturi must not be changed)

a) Remove mains pipework from rear then remove back panel to gain access to fan.

b) Disconnect plug from fan.

c) Remove bolts at flange of pipework.

d) Undo fixing that secures ignition control box to gas valve and remove.

e) Fan and valve assembly may now be lifted clear.

f) Remove fixings that secure fan to valve/venturi system. Replace in reverse order.

Check system for gas leaks.

3.5 GAS CONTROL VALVE

(Preset Venturi Must Not Be Changed)

a) Remove premix fan and valve assembly as detailed in

Section 3.4 and lift clear.

b) Remove bolts to disconnect valve from fan assembly.

c) Replace parts in reverse order and check system for gas leaks.

3.6 BURNER

a)

Remove both sides and back panel.

b)

Split pipework from both fan and burner.

c)

Remove igniter/sensor. Refer to Section 3.9.

d)

Disconnect burner bolts and carefully drop burner.

e)

Fit new gasket and replace burner.

f)

Reconnect in reverse order.

g)

Check gasket connection is sealed where fitted.

h)

Check all gas connections for leaks.

Содержание G2844F

Страница 25: ...25 SECTION 11 G2844F CIRCUIT DIAGRAM...

Страница 26: ...G2845F CIRCUIT DIAGRAM...

Страница 27: ...27 G2844F WIRING DIAGRAM...

Страница 28: ...G2845F WIRING DIAGRAM...