24

Solid Fat

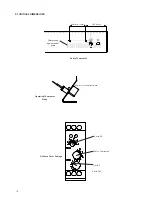

If solid fat is to be used, remove fish plate and cut fat into small pieces. Place 17kg in fry pot and pack it down.

Position fish plate upon top of the fat

. Push front end into fat lightly until front edge is below temperature

probe. Ensure that FAT MELT CYCLE

(G2845/2845F)

is selected for this process.

Note

Fish plate will lower slowly into fry pot as solid fat melts.

Warning

Check correct shortening level is achieved when all solid fat has melted. Required temperature may then be set.

Solid fat should always be heated this way to prevent overheating and burning.

WARNING

: It is dangerous to use shortening that is too old. Such shortening has a reduced flash point

temperature and is prone to surge boiling.

CAUTION

: To prevent surge boiling.

DO NOT EXCEED

recommended loads or charge pan with over-wet food

items.

NEVER leave a working appliance unattended

.

SECTION 10 - COOKING HINTS

Frying food involves many variables and the following information is a guide only.

1. Ensure frying medium is clean and free of debris.

2. When topping up with oil, ensure oil level does not exceed -MIN- line when cold and -MAX- line when hot.

3. Never overfill baskets with food product.

4. Filter oil as often as is practically possible. Remember, this can be done whilst oil is below 180°C.

5. It is advised that a skimmer is used continuously between frying batches to remove any floating debris.

Failure to do this can result in a shorter effective oil life.

6. During quiet spells, it is recommended that thermostat is turned down to a lower setting. This will conserve

energy in addition to extending expected oil life.

7. To ensure a good eating experience, fry food as near to serving time as possible.

8. After serving and when fryer has been turned off, replace lid to ensure that no foreign bodies can contaminate

frying medium.

Содержание G2844F

Страница 25: ...25 SECTION 11 G2844F CIRCUIT DIAGRAM...

Страница 26: ...G2845F CIRCUIT DIAGRAM...

Страница 27: ...27 G2844F WIRING DIAGRAM...

Страница 28: ...G2845F WIRING DIAGRAM...