23

3) Remove baskets, fish plate and crumb catcher. Soak these components in hot soapy water.

4) With drain valve open, remove any traces of debris from fry pot using a clean, damp cloth.

NOTE:

Care should be taken not to damage sensors located at pan front.

5) Remove strainer and microfilter, soak these in hot soapy water.

6) Wash, rinse and dry removed items thoroughly. Set these aside.

7) Close drain valve.

8) Fill fry pot 3/4 full with hot water.

9)

Clean pan using a soft, clean cloth and hot soapy water, rub away any stubborn staining with a

scouring pad and suitable detergent.

10) Open drain valve. Drain water into bucket below.

11) Use clean water to rinse fry pot and dry thoroughly (including inside of drain valve).

12) Close drain valve.

13) Return fish plate and baskets to pan.

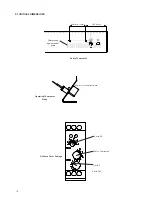

14) Remove oil bucket by pulling forward then upward.

15) Use handles and lift oil bucket to sink.

16) Pour away soiled water.

17) Thoroughly wash, rinse and dry oil bucket and oil suction pipe.

18) Replace strainer and micro filter in oil bucket and return oil bucket to cradle.

19) Fill fry pot with clean oil/solid/shortening to -MIN- mark. To relight, refer to Section 6.2.

Warning. Ensure that all fitments are thoroughly dry and clear of water before returning to appliance.

No water should be allowed to mix with the oil.

SECTION 9 - PREPARATION OF SOLID FATS/SHORTENING

COOKING HINTS

Allow approximately 10 minutes for unit to heat up from cold to required operating temperature.

CHOICE OF FRYING MEDIUM

Select a top quality medium to obtain optimum results. Shortening or solid fats can be used if necessary.

Solid fats MUST be heated carefully as these have a lower smoke point temperature than shortening.

The fryer is equipped with a fat melt cycle that will pulse heat into the fryer.

A quality shortening is a more stable frying medium. It allows longer periods of use without smoking or

foaming. It will also give food a better flavour.

Quality shortening has a higher flashpoint temperature and will reduce gumming around the pan.

Regular filtering will help improve lifespan of the medium.

WARNING

- NEVER MIX SHORTENING AND SOLID FAT!

Charging The Pan

Prior to operation, clean fry pot out using hot water and detergent.

Rinse out and dry thoroughly. (including inside of drain valve).

Ensure drain valve is closed. Fill fry pot with cold shortening to MIN level mark on basket hanging rail.

Approximate maximum oil level capacity is 18 litres.

Содержание G2844F

Страница 25: ...25 SECTION 11 G2844F CIRCUIT DIAGRAM...

Страница 26: ...G2845F CIRCUIT DIAGRAM...

Страница 27: ...27 G2844F WIRING DIAGRAM...

Страница 28: ...G2845F WIRING DIAGRAM...