21

7.3.1 Filter Oil into Receptacle (Oil Bucket) as 7.2 Above

Warning

Removal of fryer oil must be carried out under controlled circumstances. Refer to Health and Safety, Manhandling

and Local Dispensing of Oil regulations.

7.3.2 Manual Removal of Oil from Receptacle (Oil Bucket)

1. Slide receptacle forward, and remove strainer basket and microfilter.

Note:

The oil container may be heavy. Drain small amounts at a time if necessary, before lifting container. Manual

handling regulations should be observed.

This practice should be carried out when oil is lukewarm.

Weight of Empty oil filter

– 4.25kg

Each litre of oil

– approx 1kg.

2. Using handles provided, lift receptacle clear by pulling up and forward.

Note

Care should be taken not to pull runner cradle out during this operation. Be careful also, not to spill oil.

3. Lift o i l c o n t a i n e r and dispense according to local regulations.

4. Replace strainer basket and microfilter.

5. Replace oil container in reverse order.

Note

Cleaning of filters and oil container should be carried out on a regular basis as required.

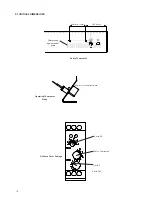

7.3.3 Using Oil Decanting Hose

(Refer to Figure 5)

Warning

The decanting hose must ONLY be used to decant oil from unit o il co nt ain er to recommended disposal

vessel. Always wear the recommended Personal Protective Equipment

(PPE)

to prevent injury as the hose

and components will be HOT.

DANGER

NEVER operate decanting hose for purposes other than recommended.

With pump OFF and fry pot empty:

a) Disconnect oil return pipe from flue quick-release connection.

b) Connect decanting hose to flue quick-release connection and connect oil return pipe to other end of hose.

c) Using handle, point hose into disposal vessel.

d) Press filtration pump switch to switch pump on.

e) When oil has decanted, press filtration pump switch to switch pump off.

f) When cooled to touch temperature, disconnect d e c a n t i n g hose from flue quick-release and oil return pipe.

g) Reconnect oil return pipe to quick release connection.

Содержание G2844F

Страница 25: ...25 SECTION 11 G2844F CIRCUIT DIAGRAM...

Страница 26: ...G2845F CIRCUIT DIAGRAM...

Страница 27: ...27 G2844F WIRING DIAGRAM...

Страница 28: ...G2845F WIRING DIAGRAM...