58

HPS-III-Heißkanalsystem_Inbetriebnahme-System-Einzeldüsen-L2X-NV_BA_V-2-0_EN

Start-up of a HPS III hot runner system

1.

Precondition: the hot runner system is already filled with

the new material!

2.

Switch off the hot runner. Let the mould cooling stay

switched on.

3. Dismantle the contour plate in cold condition.

By doing this the nozzle tips become accessible.

4. Switch the hot runner on again.

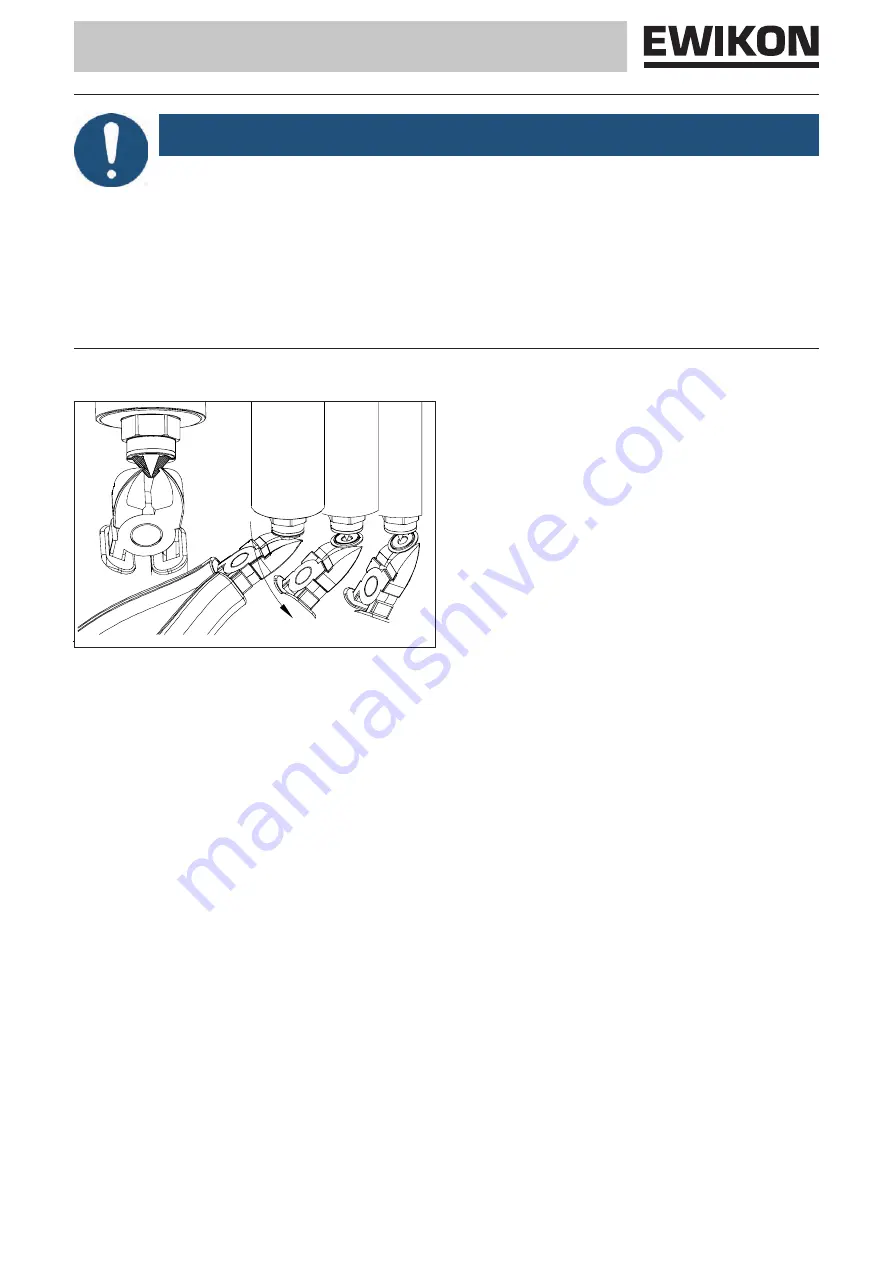

5. As soon as the cap, the area of frozen plastic between

nozzle tip and gate, starts to melt partially around the tip

it can be removed by using a side cutter.

Close the side cutter only so far that the cap can be

pulled off. Closing it too far and with too much

pressure can damage the heat conductive tip or the

valve pin if a valve gate system is used.

6. Remaining material residues at the nozzle tip can be

removed by using a wire brush (soft wire, see chapter

„5.3.1 Tools and operating materials“).

7.

Switch off the hot runner. Let the mould cooling stay

switched on.

8. Install the contour plate in cold condition.

9. Switch on the hot runner.

10. After processing temperature is reached start moulding.

Picture 40: Removal of cap

z321-11

Removal of „cap“

NOTE!

If despite of intensive purging old material still remains visible in the moulded part (visible flow marks on the

surface or inside transparent parts) the so called „cap“ the area of frozen plastic between nozzle tip and gate

must be removed.

Recommended tools for the following installation steps

The use of non-approved assembly tools may result in damage to the HPS III nozzles.

•

Wire brush, soft (

preferably brass wire, do not use brass-coated wire

).

•

Side cutter (preferably side cutter for electronics)

Содержание L2X

Страница 2: ......

Страница 6: ...6 HPS III L2X Hei kanalsystem_Inhalt_BA_V 2 0_EN...

Страница 36: ...36 HPS III L2X Hei kanalsystem_Montage_BA_V 2 0_EN...