ESAB ET 186i AC/DC

BASIC WELDING GUIDE 4-10 Manual 0-5425

FAULT

CAUSE

REMEDY

5 Portions of the

weld run do not

fuse to the surface

of the metal or

edge of the joint.

A Small electrodes used on

heavy cold plate.

A Use larger electrodes and preheat the plate.

B Welding current is too low. B Increase welding current.

C Wrong electrode angle.

C Adjust angle so the welding arc is directed more

into the base metal.

D Travel speed of electrode is

too high.

D Reduce travel speed of electrode.

E Scale or dirt on joint surface. E Clean surface before welding.

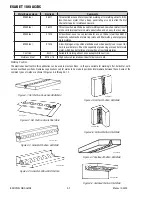

Art: A-04972

Figure 2: Example of Lack of Fusion

6 Gas pockets or

voids in weld

metal (porosity)

A High levels of sulphur in

steel.

A Use an electrode that is designed for high

sulphur steels.

B Electrodes are damp.

B Dry electrodes before use.

C Welding current is too high. C Reduce welding current.

D Surface impurities such as

oil, grease, paint, etc.

D Clean joint before welding.

E Welding in a windy

environment.

E Shield the weld area from the wind.

F Electrode damaged i.e. flux

coating incomplete.

F Discard damaged electrodes and only use

electrodes with a complete flux coating.

7 Crack occurring in

weld metal soon

after solidification

commences

A Rigidity of joint.

A Redesign to relieve weld joint of severe stresses

or use crack resistance electrodes.

B Insufficient throat thickness. B Travel slightly slower to allow greater build up in

throat.

C Weld current is too high.

C Decrease welding current.

Art: A-04973

Figure 3: Example of Slag Inclusion

Table 4-2: Welding Problems SMAW (STICK)