ESAB ET 186i AC/DC

Manual 0-5425

4-3 BASIC WELDING GUIDE

Joint Preparations

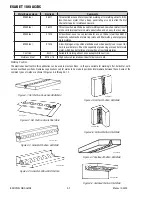

In many cases, it will be possible to weld steel sections without any special preparation. For heavier sections and for repair work

on castings, etc., it will be necessary to cut or grind an angle between the pieces being joined to ensure proper penetration of the

weld metal and to produce sound joints.

In general, surfaces being welded should be clean and free of rust, scale, dirt, grease, etc. Slag should be removed from oxy-cut

surfaces. Typical joint designs are shown in Figure 4-9.

Gap varies from

1/16” (1.6mm) to 3/16” (4.8mm)

depending on plate thickness

Joint

Open Square Butt

1/16” (1.6mm) max

1/16” (1.6mm)

Single Vee Butt Joint

Not less than

70

°

Double Vee Butt Joint

1/16” (1.6mm)

Lap Joint

Tee Joints

(Fillet both sides of the

joint)

Edge Joint

Fillet Joint

Corner Weld

Plug Weld

Plug Weld

Not less than

70

°

Single Vee Butt Joint

Not less than

45

°

1/16” (1.6mm) max

Art # A-10672

Figure 4-9: Typical Joint Designs for Arc Welding

Arc Welding Technique - A Word to Beginners

For those who have not yet done any welding, the simplest way to commence is to run beads on a piece of scrap plate. Use mild

steel plate about 1/4" (6.0mm) thick and a 1/8" (3.2mm) electrode. Clean any paint, loose scale or grease off the plate and set it

firmly on the work bench so that welding can be carried out in the downhand position. Make sure that the work clamp is making

good electrical contact with the work, either directly or through the work table. For light gauge material, always clamp the work

lead directly to the job, otherwise a poor circuit will probably result.

The Welder

Place yourself in a comfortable position before beginning to weld. Get a seat of suitable height and do as much work as possible

sitting down.

Place the work so that the direction of welding is across, rather than to or from, your body. The electrode holder lead should be

clear of any obstruction so that you can move your arm freely along as the electrode burns down. Be sure the insulation on your

cable and electrode holder is not faulty, otherwise you are risking an electric shock.