ESAB ET 186i AC/DC

Manual 0-5425 3-13 INSTALLATION, OPERATION AND SETUP

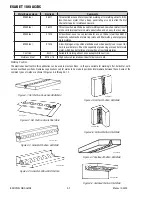

Programming Parameter

Adjustment Device

Display

Low Current

The lowest point in the pulse is

called the Low Current.

Amps

5 to 200A (DC HF TIG mode)

30 to 200A (AC LIFT TIG mode)

10 to 200A (AC HF TIG mode)

Pulse Width

This parameter sets the

percentage on time of the PULSE

FREQUENCY for High weld

current when the PULSE is ON.

V

SEC

%

Hz

Volts

15 to 80%

Pulse Frequency

This parameter sets the PULSE

FREQUENCY when the PULSE is

ON.

V

SEC

%

Hz

Volts

0.5 to 200 Hz

Down Slope

This parameter operates in TIG

modes only and is used to set

the time for the weld current

to ramp down, after the torch

trigger switch has been pressed,

to crater current. This control is

used to eliminate the crater that

can form at the completion of a

weld.

V

SEC

%

Hz

Volts

0.0 to 25.0 seconds

Crater Current

This parameter operates in (4T)

TIG modes only and is used to

set the finish current for TIG.

The CRATER Current remains

ON until the torch trigger switch

is released after it has been

depressed.

Note: The maximum crater

current available will be limited to

the set value of the weld current.

Amps

5 to 200A (DC TIG mode)

30 to 200A (AC TIG mode)

10 to 200A (AC HF TIG mode)

Post Flow

This parameter operates in TIG

modes only and is used to adjust

the post gas flow time once

the arc has extinguished. This

control is used to dramatically

reduce oxidation of the tungsten

electrode.

V

SEC

%

Hz

Volts

0.0 to 60.0 seconds