ESAB ET 186i AC/DC

BASIC WELDING GUIDE 4-2 Manual 0-5425

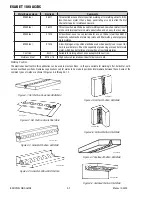

Art # A-07687

Figure 4-1: Flat Position, Down Hand Butt Weld

Art # A-07688

Figure 4-2: Flat Position, Gravity Fillet Weld

Art # A-07689

Figure 4-3: Horizontal Position, Butt Weld

Art # A-07690

Figure 4-4: Horizontal-Vertical (HV) Position

Metal Being Joined

Electrode

Comments

Mild Steel

E6011

This electrode is used for all-position welding or for welding on rusty, dirty,

less-than-new metal. It has a deep, penetrating arc and is often the first

choice for repair or maintenance work.

Mild Steel

E6013

This all-position, electrode is used for welding clean, new sheet metal. Its soft

arc has minimal spatter, moderate penetration and an easy-to-clean slag.

Mild Steel

E7014

All positional, ease to use electrode for use on thicker steel than E6013.

Especially suitable sheet metal lap joints and fillet welds, general purpose

plate welding.

Mild Steel

E7018

A low-hydrogen, all-position electrode used when quality is an issue or for

hard-to-weld metals. It has the capability of producing more uniform weld

metal, which has better impact properties at low temperatures.

Cast Iron

Eni-Cl

Suitable for joining all cast irons except white cast iron.

Stainless Steel

E318L-16

High corrosion resistances. Ideal for dairy work etc.

Welding Position

The electrodes dealt with in this publication can be used in most positions, i.e. they are suitable for welding in flat, horizontal, verti-

cal and overhead positions. Numerous applications call for welds to be made in positions intermediate between these. Some of the

common types of welds are shown in Figures 4-5 through 4-12.

Art A-07691

Figure 4-5: Vertical Position, Butt Weld

Art # A-07692

Figure 4-6: Vertical Position, Fillet Weld

Art# A-07693

Figure 4-7: Overhead Position, Butt Weld

Art # A-07694

Figure 4-8: Overhead Position, Fillet Weld