Specifications

| 77

Probes

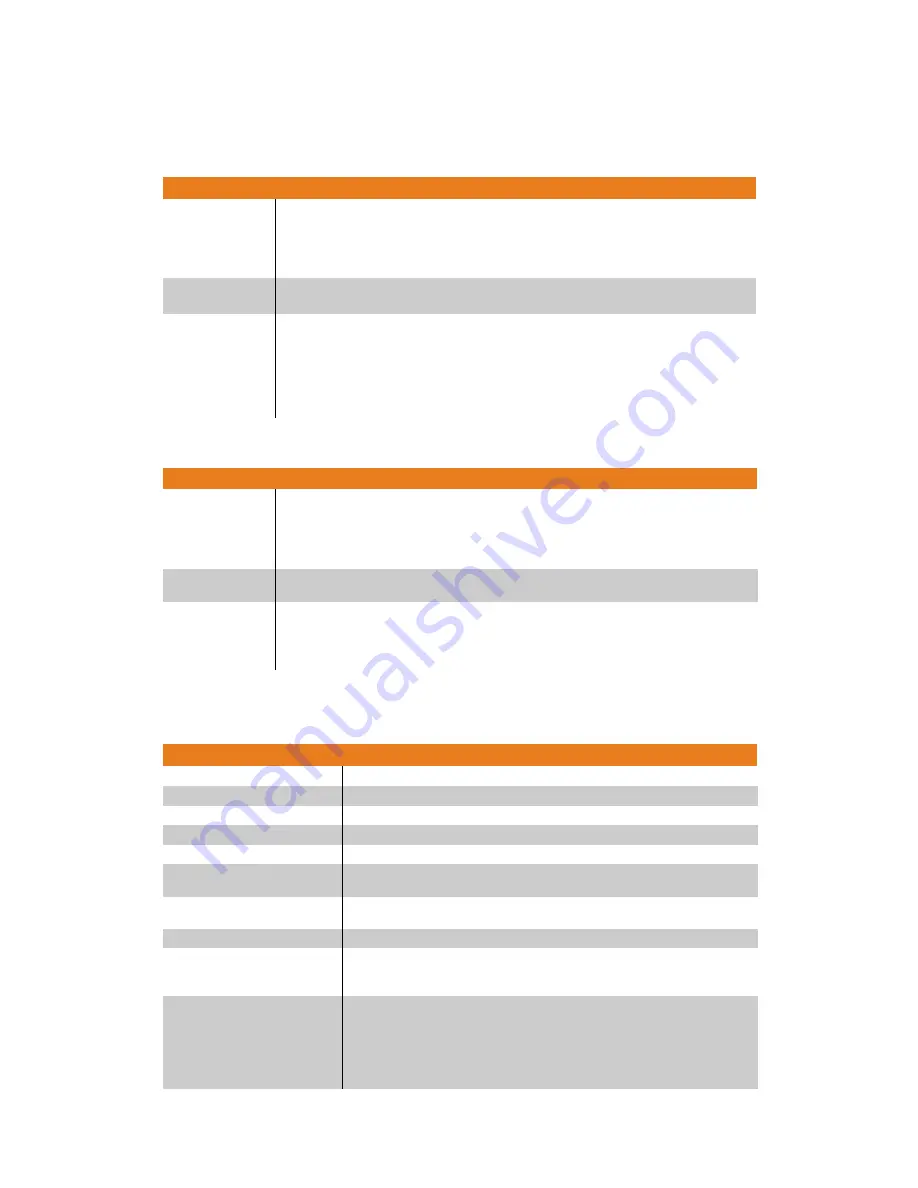

Table 8-3

Single-element

probes specifications

Specification

Value

Models

Liftoffs: 0–305 mm (0–12in), 0-203 mm (0-8 in), 0-76 mm (0-3 in)

Clip-on encoder

Remote control keypad

Lyft 27-pin Fischer connector

Heavy-Duty 5m (16.4 ft) cable

Testing

temperatures

Carbon steel structures: –150 °C to 500 °C (–238 °F to 932 °F)

Weather jackets: maximum 70 °C (158 °F)

Accessories

Extension cable, from 15 m (50 ft) to 100m (328f)

Telescopic extension pole with embedded remote control keypad, up to 4.6 m (15 ft)

long

See page 7 and the PEC probe catalog for further

details

Table 8-4

Array

probes specifications

Specification

Value

Models

Liftoffs: 0–50 mm (0–2in)

Clip-on encoder

Remote control keypad

Lyft 27-pin Fischer connector

Heavy-Duty 5m (16.4 ft) cable

Testing

temperatures

Carbon steel structures: –150 °C to 500 °C (–238 °F

to 932 °F) Weather jackets: maximum 70 °C (158 °F)

Accessories

Extension cable, from 15 m (50 ft) to 100m (328f)

Scab mat for constant liftoff

See page 9 and the PEC probe catalog for further details

Performances

Table 8-5

Performances

Specification

Value

Nominal wall thickness

Up to 100 mm (4 in)

Insulation (liftoff)

0–305 mm (0–12 in)

Dynamic data acquisition

Up to 15 points/s (GD and GDA models only)

Dynamic scan speed

Up to 75 mm/s (3 in/s) (GD and GDA models only)

Grid-mapping scan speed

Instant, less than 1 second (typical)

Smallest detectable defect

volume

15 % of footprint volume (footprint

×

WT)

Minimum measurable

remaining WT

15 % from nominal

Pipe diameter

Down to 25 mm (1 in)

Weather jackets

•

Stainless steel up to 1.5 mm (0.06 in)

•

Aluminum up to 1 mm (0.04 in)

•

Galvanized steel up to 0.5 mm (0.02 in)

SmartPULSE

•

Automatic configuration of PEC pulser-receiver parameters

•

Full thickness sensitivity (OD and ID flaw detection)

•

Reliable measurements with liftoff variations, weather jackets

overlaps, straps, and corrosion scabs

•

One-point calibration (on nominal wall or known thickness value), auto-

normalization, and repeatability optimization

Содержание LYFT

Страница 1: ...i EDDYFI LYFT Corrosion Assessment Redefined User s Manual...

Страница 11: ...General Precautions and conventions xi General Precautions and conventions...

Страница 17: ...Lyft System Overview 1 Chapter 1 Lyft System Overview...

Страница 26: ...10 eddyfi com Figure 1 9 Lyft in the horizontal position Figure 1 10 Lyft in the tilted position...

Страница 30: ...14 eddyfi com...

Страница 31: ...Software overview 15 Chapter 2 Software overview...

Страница 47: ...Workflow overview 31 Chapter 3 Workflow overview...

Страница 48: ...32 eddyfi com TYPICAL Inspection Workflow Figure 3 1 Typical inspection workflow...

Страница 68: ...52 eddyfi com...

Страница 69: ...Lyft PRO software 53 Chapter 4 Lyft PRO software...

Страница 73: ...Lyft PRO software 57...

Страница 74: ...58 eddyfi com Chapter 5 Preferences...

Страница 78: ...62 eddyfi com...

Страница 79: ...Keypad and Keyboard Functions 63 Chapter 6 Keypad and Keyboard Functions...

Страница 81: ...Maintenance and Troubleshooting 65 Chapter 7 Maintenance and Troubleshooting...

Страница 90: ...74 eddyfi com...

Страница 91: ...Specifications 75 Chapter 8 Specifications...

Страница 94: ...78 eddyfi com...

Страница 95: ...Connector reference 79 Appendix A Connector reference...

Страница 99: ...Using the Optional Harness 83 Appendix B Using the Optional Harness...

Страница 109: ...Setting Up the Extension Pole 93 Appendix C Setting Up the Extension Pole...

Страница 113: ...Using the array probe straps 97 Appendix D Using the array probe straps...

Страница 119: ...License management 103 Appendix E License management...

Страница 121: ...License management 105 Today Two weeks later YourComputerID...