LCR7000 & RHEOSIGHTS P/N: 974194 |

Rev: A

|

ECO: 52468

www.dynisco.com

From lab to production,

providing a window into the process

-58-

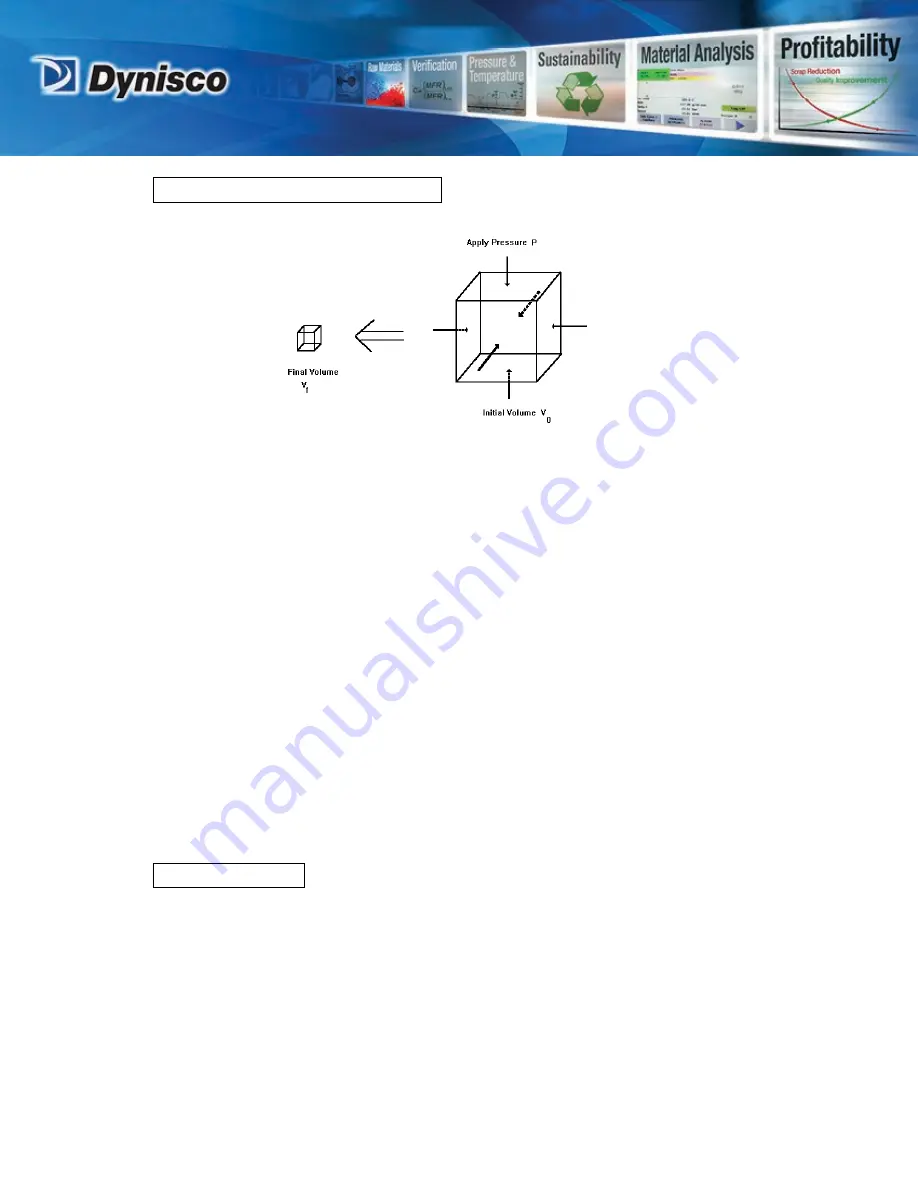

Stress is the applied pressure, P.

Strain is the change in volume divided by the original volume.

Most real flows, such as those seen in the rheometer, contain a combination of the three

fundamental deformation geometries shown above. When the molten material is

compressed in the barrel it undergoes a volumetric compression, which increases its

density slightly. Material flowing from the barrel into the entrance of the die experiences an

extensional deformation. (Imagine stretching the material in the barrel until it is thin

enough to fit through the die and you understand the extension aspect of the flow.) Finally,

in the capillary die the material immediately adjacent to the walls is stationary (more on

this assumption later), yet the material in the center of the capillary is moving very fast.

(The die wall is like the bottom plate in the simple shear geometry and the center of the

stream is similar to the top plate.) Capillary rheometers are designed primarily to measure

the shear viscosity of a material. With some additional measurements, extensional

viscosity can also be estimated. Limited volumetric data (PVT) can be collected for the

molten material using a solid die, special sealing plunger and pressure transducer.

τ

µ γ

=

Shear Stress

Newtonian Shear

Viscosity Rate

b.

Volumetric Deformation (BULK)

2.

Newton’s Law