Description of SETTINGS Window

10

Chapter 1 Operation screen

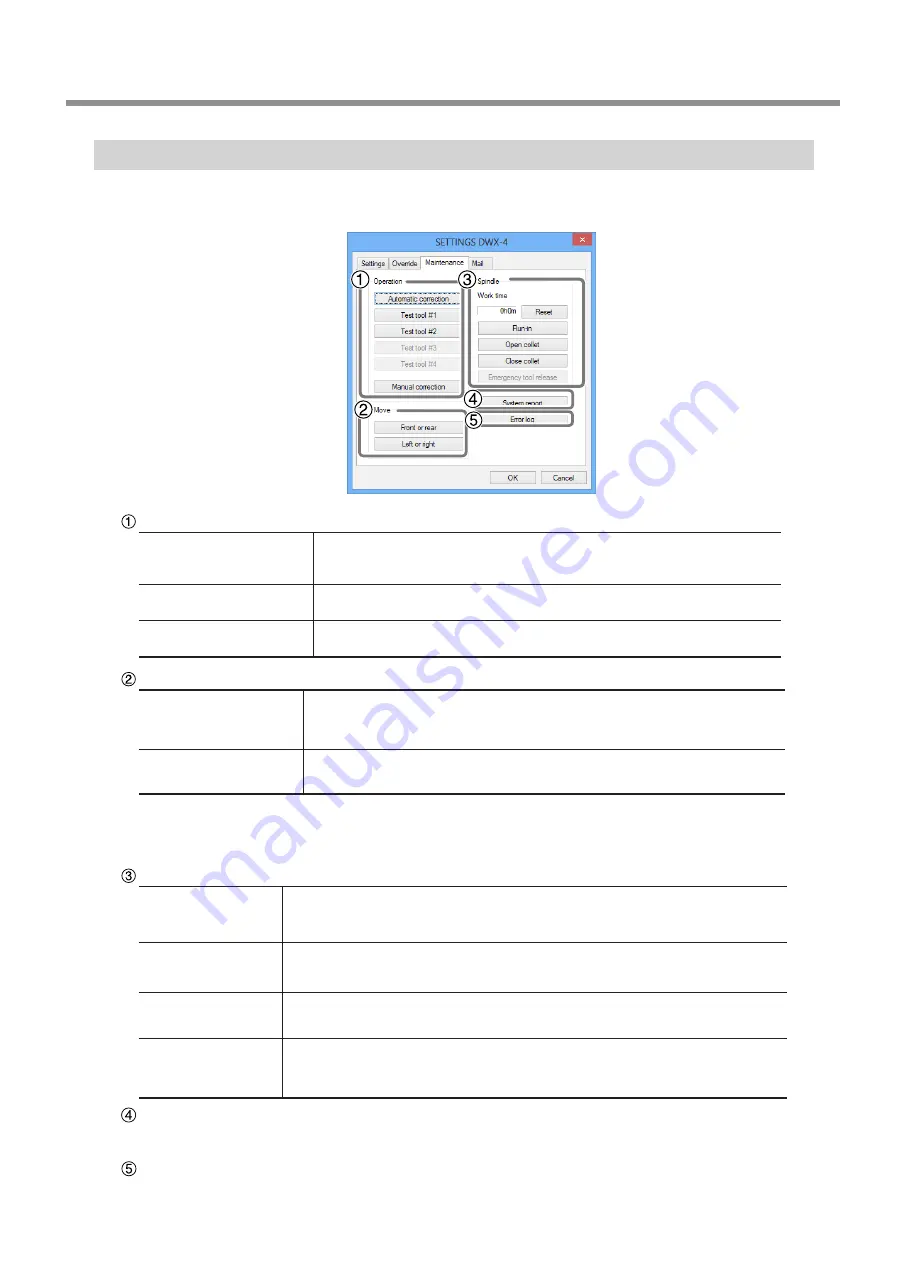

"Maintenance" Tab

In this tab, you can make the operations related to maintenance, such as automatic correction of the milling machine and system

report. When more than one machine is connected, the machine selected in the top window is the target of these operations.

Operation

Automatic correction

Perform automatic correction of the milling machine after the machine was

installed or relocated or when the cutting position is incorrect.

P. 29, "Correction of Milling Machine"

Test tool **

(** refers to #1 to #4)

Perform a test to replace the tool.

*#3 to 4 are used when using ZAT-4D (4 position ATC) which is an optional item.

Manual correction

Use this function when you want to correct the machine manually.

P. 12, ""Manual correction" Dialog"

Move

(These buttons are used to perform cleaning of the machine.)

Front or rear

The rotary axis unit will move forward or backward by clicking on this button.

Whenever the movement is complete, "Operation was completed" is displayed.

Click "OK."

Left or right

The spindle unit will move to the right or left by clicking on this button. When

the movement is complete, "Operation was completed" is displayed. Click "OK."

* When the operation button of the built-in panel of the machine is pressed, the spindle head and table return to the

VIEW position . (The spindle unit returns to the right end in the highest position, and the rotary axis unit returns to the

forefront position)

Spindle

Work time

The work time of the spindle unit will be displayed. After the replacement of the spindle

unit, click on "Reset" to reset the value at 0.

P. 38, "Replacing of the Spindle Unit"

Run-in

You can perform run-in operation for the spindle. When installing and moving the

machine, or replacing the spindle unit.

P. 28, "Spindle Run-in (Warm-up)"

Open collet

Close collet

You can open or close the collet. Use this function to retighten the collet.

P. 31, "Retightening the Collet"

Emergency tool

release

The collet can be opened before initialization. Use this function if initialization cannot

be performed when, for example, the tool gets snagged on something. It will become

valid by turning on the power with the front cover open.

System report

You can display the serial number, firmware version, and total work time, etc. of the machine in a report.

You can save the system report in a text file by clicking "Save" in the System report window.

Error log

You can display the logs of the errors which have occurred so far. You can save the error log in a text file by clicking "Save"

in the error log window.

Содержание DWX-4

Страница 53: ...R6 171006 FA01214...