27

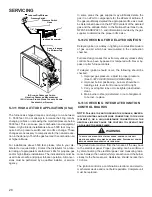

SERVICING

WARNING

HIGH VOLTAGE

Disconnect ALL electrical power and shut off gas supply

before servicing or installing.

Gas

Rate

Range

Nominal

High Stage

9.7 to 10.3" w.c. 10.0" w.c.

Low Stage

5.7 to 6.3" w.c. 6.0" w.c.

Manifold Gas Pressure

Propane Gas

S-308 CHECKING HOT SURFACE IGNITOR

120V Mini Igniter Single Stage - furnaces use a 120V car

-

bide mini igniter for ignition. The normal operating tempera

-

ture is approximately 2550°F - 2876°F. At room temperature

a good igniter will have an ohm reading range of 50 - 300.

WARNING

Disconnect ALL Gas and Electric Power Supply.

1. Remove burner compartment door to gain access to

the ignitor.

2.

Ignitor cool - approximately 70 - 77°F.

3.

Disconnect the ignitor from the Ignition Control.

4.

Using an ohmmeter measure the resistance of the

ignitor:

Mini Igniter

: Carbide Mini Igniter should read between

30 to 300 ohms.

5. Reconnect ignitor.

WARNING

Line Voltage now present.

6.

Place unit in heating cycle, measure current draw of

ignitor during preheat cycle.

Models using 120V Mini Igniter:

Should read approximately 1 amp maximum. The

steady state current at 120V is a nominal of .7 plus or

minus .3 amps.

7.

After checking and/or replacing of hot surface ignitor,

reinstall burner compartment door and verify proper

unit operation.

120V Silicone Nitride Igniter

- (pt #

0130F00008) furnaces with a 120V silicone nitride

igniter; The normal operating temperature is approx-

imately 2156° F - 2678° F. At room temperature the

igniter ohm reading should be from 37-68 ohms.

S-309 CHECKING FOR FLASHBACK

Flashback will also cause burning in the burner venturi, but

is caused by the burning speed being greater than the gas-

air flow velocity coming from a burner port.

Flashback may occur at the moment of ignition, after a burn

-

er heats up or when the burner turns off. The latter is known

as extinction pop.

Since the end results of flashback and delayed ignition can

be the same (burning in the burner venturi) a definite attempt

should be made to determine which has occurred.

If flashback should occur, check for the following:

1. Improper gas pressure - adjust to proper pressure

(See S-307 CHECKING GAS PRESSURE).

2.

Check burner for proper alignment and/or replace

burner.

3.

Improper orifice size - check orifice for obstruction.

S-310 CHECKING PRESSURE SWITCH

The pressure switch a safety device to prevent the combus

-

tion cycle from occurring with inadequate venting caused by a

restricted or blocked vent pipe on the 80% and 90% furnaces.

WARNING

HIGH VOLTAGE

Disconnect ALL power before servicing or in

-

stalling this unit. Multiple power sources may

be present. Failure to do so may cause proper

-

ty damage, personal injury or death.

1. Remove burner compartment door to gain access to

pressure switch(es).

2.

Remove wires from the pressure switch(es) electrical

terminals.

3.

Using a VOM check from common terminal to NC

(Normally Closed) - should read open.

If switch reads as above proceed to Step 4, otherwise re

-

place control.

4.

Remove the pressure control hose from the control

and interconnect with an inclined manometer as

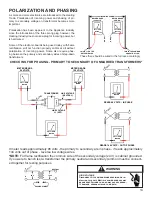

shown in the following figures.