18

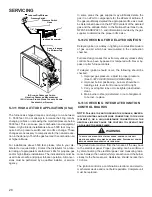

SERVICING

S-1 CHECKING VOLTAGE

WARNING

HIGH VOLTAGE

Disconnect ALL power before servicing or in

-

stalling this unit. Multiple power sources may

be present. Failure to do so may cause proper

-

ty damage, personal injury or death.

1. Remove the burner door to gain entry to the Junction

Box.

2.

Remove cover from the Junction Box and gain ac

-

cess to incoming power lines.

With Power ON:

WARNING

Line Voltage now present.

3.

Using a voltmeter, measure the voltage across the

hot and neutral connections.

NOTE: To energize the furnace, the Door Interlock

Switch must be engaged at this point.

4.

No reading - indicates open wiring, open fuse, no

power, or faulty Door Interlock Switch from unit to

fused disconnect service. Repair as needed.

5.

With ample voltage at line voltage connectors, ener

-

gize the furnace blower motor by jumpering terminals

R to G on the integrated ignition control.

6.

With the blower motor in operation, the voltage

should be 115 volts ± 10 percent.

7.

If the reading falls below the minimum voltage, check

the line wire size. Long runs of undersized wire can

cause low voltage. If wire size is adequate, notify the

local power company of the condition.

8.

After completing check and/or repair, replace Junc

-

tion Box cover and reinstall the service panel doors.

9.

Turn on electrical power and verify proper unit

operation.

S-2 CHECKING WIRING

WARNING

Disconnect ALL power before servicing.

1.

Check wiring visually for signs of overheating, dam

-

aged insulation and loose connections.

2.

Use an ohmmeter to check continuity of any suspect

-

ed open wires.

3.

If any wires must be replaced, replace with AWM,

105°C. 2/64 thick insulation of the same gauge or its

equivalent.

CHECKING THERMOSTAT, WIRING AND

ANTICIPATOR

S-3A THERMOSTAT AND WIRING

WARNING

Disconnect ALL power before servicing.

1. Remove the blower compartment door to gain access

to the thermostat low voltage wires located at the

furnace integrated control module terminals.

2.

Remove the thermostat low voltage wires at the fur

-

nace control panel terminal board.

3. Jumper terminals R to W on the integrated ignition

control.

With Power On (and Door Interlock Switch closed):

WARNING

Line Voltage now present.

4.

Induced Draft Motor must run and pull in pressure

switch.

5.

If the hot surface ignitor heats and at the end of the

ignitor warm-up period the gas valve opens and the

burners ignite, the trouble is in the thermostat or

wiring.

6.

With power off, check the continuity of the thermostat

and wiring. Repair or replace as necessary.

If checking the furnace in the air conditioning mode, proceed

as follows.

7.

With power off, Jumper terminals R to Y to G.

8. Turn on the power.

9.

If the furnace blower motor starts and the condens

-

ing unit runs, then the trouble is in the thermostat or

wiring. Repair or replace as necessary.

10.

After completing check and/or repair of wiring and

check and/or replacement of thermostat, reinstall

blower compartment door.

11.

Turn on electrical power and verify proper unit

operation.

S-3B HEATING ANTICIPATOR

On older thermostats the heating anticipator is a wire wound

adjustable heater which is energized during the “ON” cycle

to help prevent overheating of the conditioned space.

The anticipator is a part of the thermostat and if it should

fail for any reason, the thermostat must be replaced. Some

thermostats have a cycle rate adjustment switch to set cy-

cles per hour.