28

SERVICING

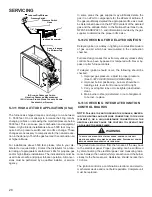

Induced Draft Blower

Pressure Switch

Pressure Switch

Hose

1/4" Tee

Hose to Induced

Draft Blower Tap

Inclined Manometer

ID Blower Pressure Switch

Negative Pressure Measurement

(80% Upflow Single-Stage Furnace Shown,

Counterflow Similar)

S-311 HIGH ALTITUDE APPLICATION (USA)

The furnace as shipped requires no change to run between

0 - 5500 feet. Do not attempt to increase the firing rate by

changing orifices or increasing the manifold pressure below

5500 feet. This can cause poor combustion and equipment

failure. High altitude installations above 5500 feet may re

-

quire both a pressure switch and an orifice change. These

changes are necessary to compensate for the natural reduc

-

tion in the density of both the gas fuel and the combustion air

at higher altitude.

For installations above 5500 feet, please refer to your dis

-

tributor for required kit(s). Contact the distributor for a tabu

-

lar listing of appropriate manufacturer’s kits for propane gas

and/or high altitude installations. The indicated kits must be

used to insure safe and proper furnace operation. All conver

-

sions must be performed by a qualified installer, or service

agency.

In some areas the gas supplier may artificially derate the

gas in an effort to compensate for the effects of altitude. If

the gas is artificially derated the appropriate orifice size must

be determined based on the BTU/ft3 content of the derated

gas and the altitude. Refer to the National Fuel Gas Code,

NFPA 54/ANSI Z223.1, and information provided by the gas

supplier to determine the proper orifice size.

S-312 CHECKING FOR DELAYED IGNITION

Delayed ignition is a delay in lighting a combustible mixture

of gas and air which has accumulated in the combustion

chamber.

Furnace design makes this extremely unlikely unless safety

controls have been by-passed or tampered with. Never by-

pass or alter furnace controls.

If delayed ignition should occur, the following should be

checked:

1. Improper gas pressure - adjust to proper pressure

(See

S-307 CHECKING GAS PRESSURE

).

2. Improper burner positioning - burners should be in

locating slots, level front to rear and left to right.

3. Carry over (lighter tube or cross lighter) obstructed -

clean.

4.

Main burner orifice(s) deformed, or out of alignment

to burner - replace.

S-313 CHECKING INTEGRATED IGNITION

CONTROL BOARDS

NOTE: Failure to earth ground the furnace, revers

-

ing the neutral and hot wire connection to the line

(polarity), or a high resistance connection in the

neutral line may cause the control to lockout due

to failure to sense flame.

WARNING

To avoid the risk of electrical shock, wiring to the unit

must be properly polarized and grounded. Disconnect power

before performing service listed below.

The ground wire must run from the furnace all the way back

to the electrical panel. Proper grounding can be confirmed

by disconnecting the electrical power and measuring resis-

tance between the neutral (white) connection and the burner

closest to the flame sensor. Resistance should be less than

10 ohms.

The ignition control is a combination electronic and electro-

mechanical device and is not field repairable. Complete unit

must be replaced.