29

SERVICING

WARNING

Line Voltage now present.

1.

Check for 120 volts from Line 1 (Hot) to Line 2 (Neu

-

tral) at the ignition control. No voltage, check the door

switch connections and wire harness for continuity.

2.

Check for 24 volts from W to C terminal on the

ignition control. No voltage. Check transformer, room

thermostat, and wiring.

If you have 24 volts coming off the transformer but

receive approximately 13 volts on the terminal board

between (C) and (R), check for blown fuse.

3.

Check for 120 volts to the induced draft blower by

measuring voltage between Pin 1 (on the 2-pin con-

nector) and Line (Neutral) on the control board. No

voltage, replace ignition control.

4.

If voltage is present in Steps 1 through 3 and the

induced draft blower is operating, check for 120 volts

to the ignitor during the preheat cycle. Measure volt-

age between Pin 2 (on the 2-pin connector) and Line

(Neutral) on the control board. No voltage, check

pressure switch.

5.

After the ignitor warmup time, begin checking for 24

volts to the gas valve. Voltage will be present for seven

seconds only if proof of flame has been established.

S-314 CHECKING FLAME SENSOR

A flame sensing device is used in conjunction with the igni

-

tion control module to prove combustion. If proof of flame is

not present the control will de-energize the gas valve and

“retry” for ignition or lockout.

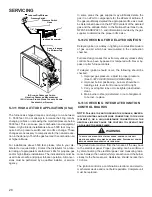

The following drawings illustrate from a bottom view, the ap

-

proximate distances for the ignitor and flame sensor to the

gas in shot burner. You will note they are in the main burner

stream, not in the carry over ports as shown in the following

figure.

Flame Sensor

Models with Integrated Ignition

Control & Flame Sensor Probe

(80% Upflow Model Shown, Counterflow Similar)

WARNING

HIGH VOLTAGE

Disconnect ALL power before servicing or in

-

stalling this unit. Multiple power sources may

be present. Failure to do so may cause proper

-

ty damage, personal injury or death.

1.

Disconnect the blue flame sensor wire from the

sensor.

2. Connect a micro-amp meter in series with this wire

and the sensor terminal.

3. Place the unit into a heating cycle.

WARNING

Line Voltage now present.

4.

As soon as flame is established a micro-amp reading

should be evident once proof of flame (micro-amp

reading) is established, the hot surface ignitor will be

de-energized.

5. The Integrated Ignition controls will have 1 to 4 mi-

cro-amps. If the micro-amp reading is less than the

minimum specified, check for high resistance wiring

connections, sensor to burner gap, dirty flame sen

-

sor, or poor grounding.

6.

If absolutely no reading, check for continuity on all

components and if good - replace ignition control

module.

NOTE: Contaminated fuel or combustion air can cre

-

ate a nearly invisible coating on the flame sensor.

This coating works as an insulator causing a loss in

the flame sense signal. If this situation occurs the

flame sensor must be cleaned with steel wool.