24

SERVICING

S-305 CHECKING MAIN BURNERS

The main burners are used to provide complete combustion

of various fuels in a limited space, and transfer this heat of

the burning process to the heat exchanger.

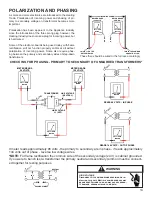

Proper ignition, combustion, and extinction are primarily due

to burner design, orifice sizing, gas pressure, primary and

secondary air, vent and proper seating of burners.

.023" - .027"

Beckett Burner

WARNING

Disconnect ALL Gas and Electric Power Supply.

In checking main burners, look for signs of rust, oversized

and undersized carry over ports restricted with foreign ma

-

terial, etc, refer to previous drawing. Burner cross-over slots

must not be altered in size.

S-306 CHECKING ORIFICES

A predetermined fixed gas orifice is used in all of these fur

-

naces. That is an orifice which has a fixed bore and position

as shown in the following drawing.

No resizing should be attempted until all factors are taken

into consideration such as inlet and manifold gas pressure,

alignment, and positioning, specific gravity and BTU content

of the gas being consumed.

The only time resizing is required is when a reduction in fir

-

ing rate is required for an increase in altitude.

Orifices should be treated with care in order to prevent dam

-

age. They should be removed and installed with a box-end

wrench in order to prevent distortion. In no instance should

an orifice be peened over and redrilled. This will change

the angle or deflection of the vacuum effect or entraining

of primary air, which will make it difficult to adjust the flame

properly. This same problem can occur if an orifice spud of a

different length is substituted.

WARNING

Disconnect ALL Gas and Electric Power Supply.

1.

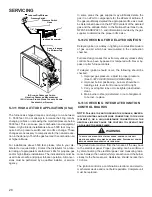

Check orifice visually for distortion and/or burrs.

2.

Check orifice size with orifice sizing drills.

3.

If resizing is required, a new orifice of the same

physical size and angle with proper drill size opening

should be installed.

A

GAS

STREAM B

The length of Dimension “A” determines the angle of Gas

Stream “B”.

DENT OR

BURR

GAS

STREAM B

A dent or burr will cause a severe deflection of the gas

stream.

S-307 CHECKING GAS PRESSURE

Gas Supply Pressure Measurement

CAUTION

To prevent unreliable operation or equipment damage, the

inlet gas supply pressure must be as specified on the unit

rating plate with all other household gas fired appliances

operating.

Gas inlet and manifold pressures should be checked and

adjusted in accordance to the type of fuel being consumed.

The line pressure supplied to the gas valve must be within

the range specified below. The supply pressure can be mea

-

sured at the gas valve inlet pressure tap or at a hose fitting

installed in the gas piping drip leg. The supply pressure must

be measured with the burners operating. To measure the

gas supply pressure, use the following procedure.