8

Propane Gas and/or High Altitude Installations

WARNING

Possible property damage, personal injury or death may

occur if the correct conversion kits are not installed. The

appropriate kits must be applied tot ensure safe and proper

furnace operation. All conversions must be performed by a

qualified installer or service agency.

This furnace is shipped from the factory configured for nat

-

ural gas at standard altitude. Propane gas installations re-

quire an orifice change to compensate for the energy con

-

tent difference between natural and propane gas.

High altitude installations may require both a pressure

switch and an orifice change. These changes are necessary

to compensate for the natural reduction in the density of both

the gas fuel and the combustion air at higher altitude.

Refer to the

Accessories Charts

in this manual or product

Specification Sheet for a tabular listing of appropriate man

-

ufacturer’s kits for propane gas and/or high altitude instal

-

lations. The indicated kits must be used to insure safe and

proper furnace operation. All conversions must be performed

by a qualified installer, or service agency.

Inlet gas supply pressures must be maintained within the

ranges specified below. The supply pressure must be con

-

stant and available with all other household gas fired appli

-

ances operating. The minimum gas supply pressure must

be maintained to prevent unreliable ignition. The maximum

must not be exceeded to prevent unit overfiring.

WARNING

Failure to follow instructions can result in bodily injury or

death. Carefully read and follow all instructions given in

this section.

WARNING

Upon completion of the furnace installation, carefully

inspect the entire flue system both inside and outside the

furnace to assure it is properly sealed. Leaks in the flue

system can result in serious personal injury or death due to

exposure to flue products, including carbon monoxide.

CAUTION

To prevent unreliable operation or equipment damage, the

inlet gas supply pressure must be as specified on the unit

rating plate with all other household gas fired appliances

operating.

Inlet gas supply pressures must be maintained within the

ranges specified below. The supply pressure must be con

-

stant and available with all other household gas fired appli

-

ances operating. The minimum gas supply pressure must

be maintained to prevent unreliable ignition. The maximum

must not be exceeded to prevent unit overfiring.

Natural Gas

Minimum: 4.5" w.c.

Maximum: 10.0" w.c.

Propane Gas

Minimum: 11.0" w.c. Maximum: 13.0" w.c.

INLET GAS SUPPLY PRESSURE

Gas Valve

This unit is equipped with a 24 volt gas valve controlled

during furnace operation by the integrated control module.

As shipped, the valve is configured for natural gas. The

valve is field convertible for use with propane gas by using

the appropriate propane gas conversion kit. Taps for mea

-

suring the gas supply pressure and manifold pressure are

provided on the valve.

NOTE: The gas supply pressure on White-Rodger

“J” model gas valve, used on single stage furnaces,

can be checked with a gas pressure test kit (Part

#0151K00000S) available through our authorized

distributors.

The gas valve has a manual ON/OFF control located on the

valve itself. This control may be set only to the “ON” or “OFF”

position. Refer to the Lighting Instructions Label located on

the furnace door.

Gas Piping Checks

Before placing unit in operation and after servicing, leak

test the unit and gas connections.

WARNING

To avoid possibility of explosion or fire, never use a match or

open flame to test for leaks.

Check for leaks using an approved chloride-free soap and

water solution, an electronic combustible gas detector, or

other approved testing methods.

NOTE: Never exceed specified pressures for testing.

Higher pressure may damage the gas valve and cause

subsequent overfiring, resulting in heat exchang

-

er failure. Disconnect this unit and shutoff valve

from the gas supply piping system before pressure

testing the supply piping system with pressures in

excess of 1/2 psig (3.48 kPa). Isolate this unit from

the gas supply piping system by closing its external

manual gas shutoff valve before pressure testing

supply piping system with test pressures equal to

or less than 1/2 psig (3.48 kPa).

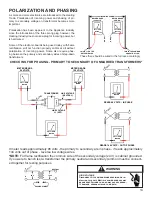

Electrical

24 Volt Thermostat Wiring

Important Note: Wiring routing must not interfere

with circulator blower operation, filter removal

or routine maintenance.