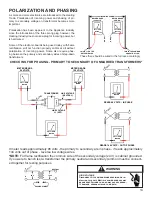

MAINTENANCE

14

14

CAUTION

If you must handle the ignitor, handle with care. Touching

the ignitor body with bare fingers, rough handling, or

vibration could result in early ignitor failure. Only a

qualified servicer should ever handle the ignitor.

Annual Inspection

The furnace should be inspected by a qualified installer, or

service agency at least once per year. This check should be

performed at the beginning of the heating season. This will

ensure that all furnace components are in proper working or

-

der and that the heating system functions appropriately. Pay

particular attention to the following items. Repair or service

as necessary.

•

Flue pipe system. Check for blockage and/or leak

-

age. Check the outside termination and the connec-

tions at and internal to the furnace.

• Combustion air intake pipe system (where applicable).

Check for blockage and/or leakage. Check the outside

termination and the connection at the furnace.

•

Heat exchanger. Check for corrosion and/or buildup

within the heat exchanger passageways.

•

Burners. Check for proper ignition, burner flame, and

flame sense.

• Wiring. Check that electrical connections are tight

and free from corrosion. Check wires for damage.

• Filters.

Air Filter

WARNING

Never operate the furnace without a filter installed as dust

and lint will build up on internal parts resulting in loss of

efficiency, equipment damage, and possible fire.

Filters must be used with this furnace. Filters do not ship

with these furnaces but must be provided by the installer for

proper furnace operation.

WARNING

HIGH VOLTAGE

Disconnect ALL power before servicing or in

-

stalling this unit. Multiple power sources may

be present. Failure to do so may cause proper

-

ty damage, personal injury or death.

Maintenance

Improper filter maintenance is the most common cause of

inadequate heating or cooling performance. Filters should

be cleaned (permanent) or replaced (disposable) every two

months or as required. It is the owner’s responsibility to keep

air filters clean. When replacing a filter, it must be replaced

with a filter of the same type and size.

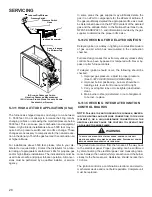

Induced Draft and Circulation Blowers

The bearings in the induced draft blower and circulator blow

-

er motors are permanently lubricated by the manufacturer.

No further lubrication is required. Check motor windings for

accumulation of dust which may cause overheating. Clean

as necessary.

Flame Sensor (Qualified Servicer Only)

Under some conditions, the fuel or air supply can create a

nearly invisible coating on the flame sensor. This coating

acts as an insulator, causing a drop in the flame sensing

signal. If this occurs, a qualified servicer must carefully clean

the flame sensor with steel wool. After cleaning, the flame

sensor output should be as listed on the specification sheet.

Burners

WARNING

HIGH VOLTAGE

Electrical components are contained in both

compartments. To avoid electrical shock, inju

-

ry or death, do not remove any internal com

-

partment covers or attempt any adjustment.

Contact a qualified service agent at once if an

abnormal flame appearance should develop.

Periodically during the heating season make a visual check of

the burner flames. Turn the furnace on at the thermostat. Wait

a few minutes since any dislodged dust will alter the normal

flame appearance. Flames should be stable, quiet, soft and

blue with slightly orange tips. They should not be yellow. They

should extend directly outward from the burner ports without

curling downward, floating or lifting off the ports.

Check the burner flames for:

1. Stable, soft and blue

2. Not curling, floating, or lifting off.

Burner Flame

Test Equipment

Test equipment list for furnace servicing should include:

1.

Multi-Meter for checking voltage & resistance

2. Clamp-on amp meter

3. Digital thermometer

4. Gas pressure test equipment

5.

Combustible gas / Carbon Monoxide detector

6. Combustion Analyzer

7. Micro-amp meter