19

SERVICING

The heating anticipator setting for furnaces covered in this

manual is 0.70 Amps.

Cooling Anticipator

The cooling anticipator is a small heater (resistor) in the ther-

mostat. During the “OFF” cycle it heats the bimetal element

helping the thermostat call for the next cooling cycle. This

prevents the room temperature from rising too high before

the system is restarted. A properly sized anticipator should

maintain room temperature within 1 1/2 to 2 degrees.

The anticipator is fixed in the subbase and is not to be re

-

placed. If the anticipator should fail for any reason, the sub

-

base must be changed.

S-4 CHECKING TRANSFORMER AND

CONTROL CIRCUIT

A step-down transformer 120 volt primary to 24 volt second

-

ary, 40 VA (Heating and Cooling Models) supplies ample ca

-

pacity of power for either operation.

WARNING

HIGH VOLTAGE

Disconnect ALL power before servicing or in

-

stalling this unit. Multiple power sources may

be present. Failure to do so may cause proper

-

ty damage, personal injury or death.

1. Remove blower compartment door to gain access

to the thermostat low voltage wires located at the

furnace integrated control module.

2.

Remove the thermostat low voltage wires at the fur

-

nace integrated control module terminals.

With Power On (and Door Interlock Switch closed):

WARNING

Line Voltage now present.

3.

Use a voltmeter, check voltage across terminals R

and C. Must read 24 VAC.

4.

No voltage indicates faulty transformer, open fuse,

bad wiring, bad splice, or open door interlock switch.

5.

Check transformer primary voltage at incoming line

voltage connections, fuse, splices, and blower door

interlock switch.

6.

If line voltage is available to the primary side of trans

-

former and not at secondary side, the transformer is

inoperative. Replace.

7.

After completing check and/or replacement of trans

-

former and check and/or repair of control circuit,

reinstall blower compartment door.

8.

Turn on electrical power and verify proper unit

operation.

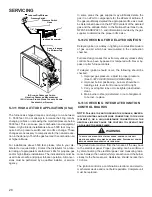

S-16 CHECKING AIR CIRCULATOR

BLOWER MOTOR (MULTI-SPEED ECM)

WARNING

Disconnect ALL power before servicing.

1. Remove blower compartment door to gain access

to the circulator blower motor and integrated ignition

control.

2.

Check for any obstruction that would keep the fan

wheel / fan motor from turning.

3.

Check wiring, the motor has two wiring harnesses,

a main harness and a control harness. The main pin

harness has:

•

White neutral wire connected to the Neutral ter-

minal on the control board.

•

Black wire connected to the CIRC H terminal on

the control board.

•

Red wire connected to the COM terminal, which

is a female spade connection next to the T1 –

T5 wires on the control board.

•

Green ground wire connected to cabinet ground

The control harness has:

•

Blue wire connected to T1 on the control board.

•

Red wire connected to T2 on the control board.

•

Orange wire connected to T3 on the control

board.

•

Black wire connected to T4 on the control board.

•

Yellow wire connected to T5 on the control

board.

The multi-speed ECM motor requires a line voltage

power supply (black connected to CIRC H and white

connected to neutral on the control board) as well as a

signal on one of the speed taps (T1-T5).

The speed tap voltage is A.C. and can vary which tap

is energized depending on DIP switch selection. The

voltage reading from any one of the speed taps is ref

-

erenced between the female COM terminal next to the

speed taps on the control board.

From COM to T1 or T2, T3, T5, you should read 24

VAC on the low voltage speed taps depending on Dip

switch settings.

CONNECTOR ID

DESCRIPTION

CONNECTOR VOLTAGE

L

LINE, L1

LINE, L1

G

GROUND

CHASSIS GROUND

N

LINE, L2

LINE, L2

C

SIGNAL COMMON 24VAC COMMON

1

TAP 1

24VAC

2

TAP 2

24VAC

3

TAP 3

24VAC

4

TAP 4

24VAC

5

TAP 5

24VAC

Motor Tap Iden

�fi

ca

�

on