23

SERVICING

S-303 INDUCED DRAFT BLOWER MOTOR

WARNING

HIGH VOLTAGE

Disconnect ALL power before servicing or in

-

stalling this unit. Multiple power sources may

be present. Failure to do so may cause proper

-

ty damage, personal injury or death.

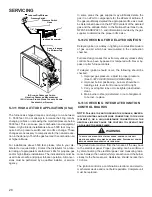

1. Remove burner compartment door to gain access to

the induced draft blower motor.

2.

Disconnect the motor wire leads from its connection

point at the induced draft motor.

3.

Using a ohmmeter, test for continuity between each

of the motor leads.

4.

Touch one probe of the ohmmeter to the motor frame

(ground) and the other probe in turn to each lead. If

the windings do not test continuous or a reading is

obtained to ground, replace the motor.

5.

If the windings have a continuity reading, reconnect

wires. Turn power on to the furnace and turn the

thermostat on in the heating mode. Check voltage for

115V at the induced draft motor terminals during the

trial for ignition. If you have 115V and the motor does

not run, replace the induced draft motor.

6.

After completing check and/or replacement of in

-

duced draft motor, reinstall burner compartment door.

7.

Turn on electrical power and verify proper unit

operation.

S-304 CHECKING GAS VALVE

(REDUNDANT)

A combination redundant operator type gas valve which pro-

vides all manual and automatic control functions required for

gas fired heating equipment is used.

The valve provides control of main burner gas flow, pressure

regulation, and 100 percent safety shut-off.

WARNING

Disconnect ALL power before servicing.

Single stage gas valves should be tested on the furnace with

24 VAC connected to the gas valve and manometers read-

ing supply line and manifold pressures.

The control is designed to open should a flame roll out oc

-

cur. An over firing condition or flame impingement on the

heat shield may also cause the control to open. If the rollout

control opens, the air circulation blower will run continuously.

WARNING

Line Voltage now present.

1. Remove the burner compartment door to gain access

to the rollout switch(es) mounted to burner bracket.

The servicer should reset the ignition control by opening

and closing the thermostat circuit. Then look for the ignitor

glowing which indicates there is power to the ignition control.

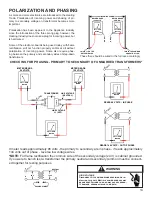

Measure the voltage between each side of the rollout control

and ground while the ignition control tries to power the gas

valve.

2.

Measure the voltage between each side of the rollout

control and ground during the ignition attempt. Refer

to the following figure.

VOLT / OHM

METER

GN

D

RED

RESET

BUTTON

COLOR

IDENTIFYING

TAB

Checking Flame Rollout Switch

a.

If no voltage is measured on either side of control

it indicates ignition control or wiring to control

problem.

b.

If voltage is measured on one side of the control

and not the other it indicates the control is open.

c.

If voltage is measured on both sides of the con

-

trol the wiring to gas valve or valve is at fault.

3.

After check and/or replacement of rollout switch,

reinstall burner compartment door and verify proper

unit operation.