20

SERVICING

WARNING

Disconnect ALL power before servicing.

S-200 CHECKING DUCT STATIC

The maximum and minimum allowable external static pres-

sures are found in the specification section. These tables

also show the amount of air being delivered at a given static

by a given motor speed or pulley adjustment.

The furnace motor cannot deliver proper air quantities (CFM)

against statics other than those listed.

Too great of an external static pressure will result in insuffi

-

cient air that can cause excessive temperature rise, resulting

in limit tripping, etc. Whereas not enough static may result in

motor overloading.

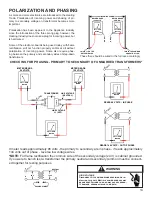

To determine proper air movement, proceed as follows:

1.

With clean filters in the furnace, use a draft gauge

(inclined manometer) to measure the static pressure

of the return duct at the inlet of the furnace. (Negative

Pressure)

2.

Measure the static pressure of the supply duct. (Pos

-

itive Pressure)

3.

Add the two (2) readings together for total external

static pressure.

NOTE: Both readings may be taken simultaneously

and read directly on the manometer if so desired. If

an air conditioner coil or Electronic Air Cleaner is

used in conjunction with the furnace, the readings

must also include theses components, as shown in

the following drawing.

4.

Consult proper tables for the quantity of air.

If the total external static pressure exceeds the minimum or

maximum allowable statics, check for closed dampers, reg

-

isters, undersized and/or oversized poorly laid out duct work.

Amana

Elec tronic Ai r Cleaner

Ca ution

High Voltage

To a void per sonal in ju ry, wait 15

secon ds afte r de -ene rgizing u nit

b efore touch in g unit in terior .

CUTAWAY OF DUCTWORK

TO EXPOSE COIL

SUPPLY

AIR

INCLINED

MANOMETER

RETURN

AIR

Checking Static Pressure

(80% Furnace Shown, 90% Similar)

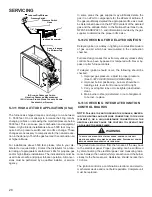

S-201 CHECKING TEMPERATURE RISE

The more air (CFM) being delivered through a given fur

-

nace, the less the rise will be; so the less air (CFM) being

delivered, the greater the rise. The temperature rise should

be adjusted in accordance to a given furnace specifications

and its external static pressure. An incorrect temperature

rise may result in condensing in or overheating of the heat

exchanger. An airflow and temperature rise table is provided

in the blower performance specification section. Determine

and adjust temperature rise as follows:

1.

Operate furnace with burners firing for approximately

ten minutes. Check BTU input to furnace - do not ex

-

ceed input rating stamped on rating plate. Ensure all

registers are open and all duct dampers are in their

final (fully or partially open) position.

2. Place thermometers in the return and supply ducts as

close to the furnace as possible. Thermometers must

not be influenced by radiant heat by being able to

“see” the heat exchanger.