22

Colortrac SmartLF Ci 24 / Ci 40 Installation and Operating Manual

PAS171 P/N: P005500 Colortrac Ltd © 2010

CHAPTER 4 SCANNER MAINTENANCE

4.1 Cleaning the CIS sensor glass

NOTE: ALWAYS SWITCH OFF AND UNPLUG THE SCANNER BEFORE CLEANING

SmartLF Ci will need regular glass cleaning maintenance. For best results follow the instructions below. See

troubleshooting section 6.2 for more help on diagnosing common maintenance issues.

Each of the five SmartLF Ci scanner CIS and glass assemblies is chemically treated and should resist scratching from

paper clips, abrasive dust and staples. Colortrac recommend that the operator takes all reasonable steps to ensure

that all scan documents are clean and free from metallic appendages and abrasive particles.

The CIS glass assemblies should be cleaned with a mild, low-smear, high quality

glass cleaner and ideally two clean lint-free cloths. Apply the cleaner to the first

cloth and use the other to wipe the sensors dry. In the event of the CISs becoming

badly scratched and affecting the scans, replacements can be ordered from your

Colortrac supplier. The Ci glass covers and sensor are integrated as a single part

and replacement should be referred to an approved service agent or distributor.

Serious maintenance issues such as electronic or a suspected internal mechanical

failure should be referred to your approved service agent for diagnosis and repair.

4.2 Cleaning the scanner roller

The scanner‟s internal paper roller should be cleaned with a damp, clean lint-free cloth. It may be necessary to use a

solvent-free foam cleaner or other cleaner compatible with EPDM (ethylene propylene diene M-class rubber) sprayed

first onto a cloth to remove more stubborn staining. Carefully rotate the drum by hand to clean the whole surface.

Never spray any cleaner directly into the scanner.

ALWAYS SWITCH OFF THE SCANNER DURING CLEANING AND NEVER TRY TO TURN THE ROLLER WHEN

THE POWER SUPPLY IS CONNECTED.

4.3 Normalisation maintenance (Ci Utilities)

The operator maintains scanner Normalisation (white point calibration) by running the scanner Utilities program.

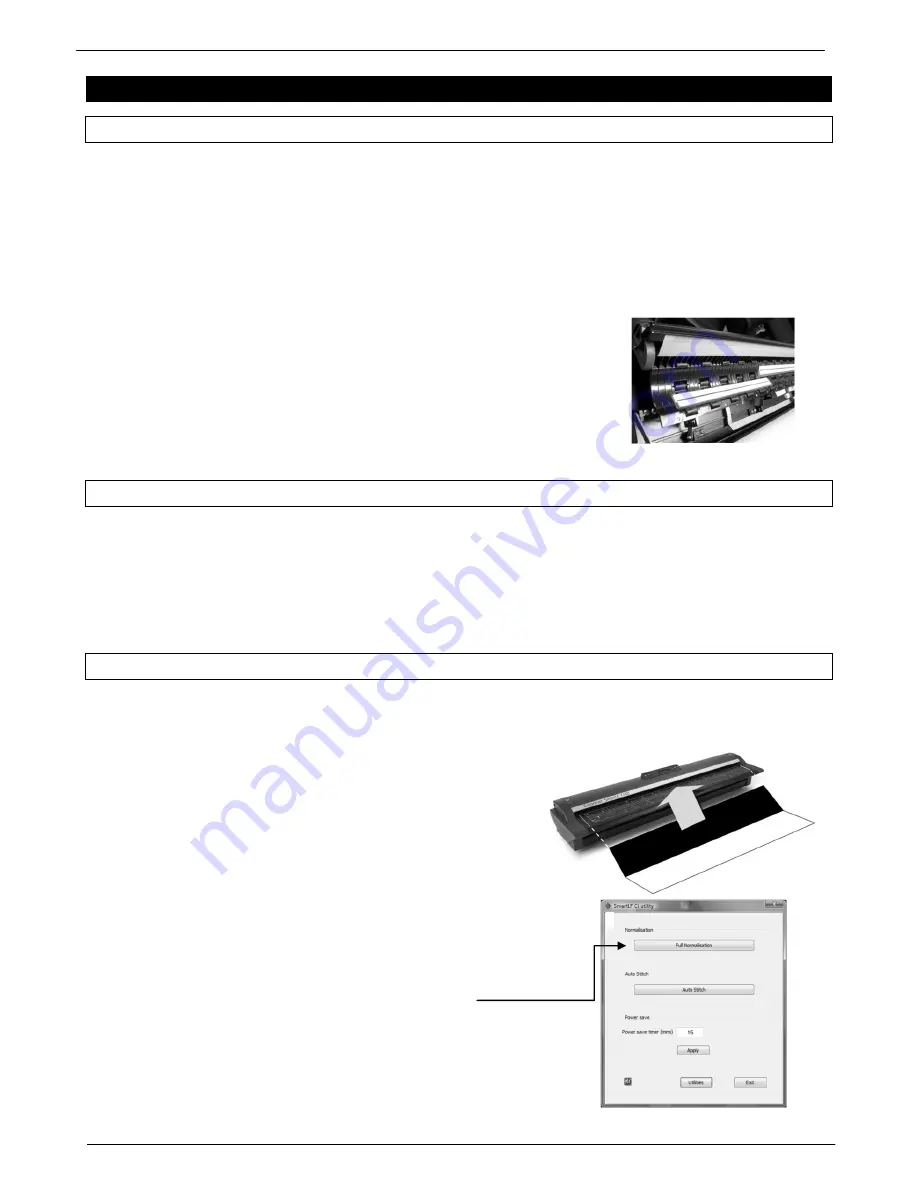

What is Full Normalisation?

The scanner can be sensitive to variations in room

temperature. Full Normalisation is part of regular scanner

maintenance and is used to maintain scanner sensor

performance.

When?

If gray or color density unexpectedly alters from sensor to

sensor or the scanner is moved or operated in different

temperature conditions.

How?

Make sure the sensor glasses and roller surface are clean then

insert the Normalisation Target face-up into the scanner, black

1

edge first. The target is made to fit inside the document guides

printed on the load tray. Allow it to load. Start Ci Utilities

(v.1.0.2.0 or later) from the program menu then press the

Full

Normalisation

button.

The word „scanning‟ will appear on the

LCD panel. Full Normalisation takes about 120 seconds.

Afterwards remove the target and store it carefully.

1

Scanners shipped with targets that do not have the black panel

should be loaded matt side up, long-edge first.

An open Ci 40 showing first and

second sensors