68

Disassembly/Inspection and Service

KohlerEngines.com

17 690 15 Rev. --

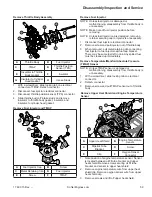

NOTE: Rings must be installed correctly. Use a piston

ring expander to install rings. Install bottom (oil

control) ring fi rst and top compression ring last.

To install new piston rings, proceed as follows:

1. Oil control ring (bottom groove): Install expander and

then rails. Make sure ends of expander are not

overlapped.

2. Middle compression ring (center groove): Install

center ring using a piston ring installation tool. Make

sure identifi cation mark is up or colored dye stripe (if

contained), is to left of end gap.

3. Top compression ring (top groove): Install top ring

using a piston ring expander. Make sure

identifi cation mark is up or colored dye stripe (if

contained), is to left of end gap.

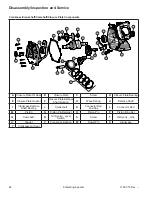

Crankshaft Inspection and Service

Inspect gear teeth of crankshaft. If teeth are badly worn,

chipped, or some are missing, replacement of crankshaft

will be necessary.

Inspect crankshaft bearing surfaces for scoring,

grooving, etc. Measure running clearance between

crankshaft journals and their respective bearing bores.

Use an inside micrometer or telescoping gauge to

measure inside diameter of both bearing bores in vertical

and horizontal planes. Use an outside micrometer to

measure outside diameter of crankshaft main bearing

journals. Subtract journal diameters from their respective

bore diameters to get running clearances. Check results

against values in Specifi cations and Tolerances. If

running clearances are within specifi cation, and there

is no evidence of scoring, grooving, etc., no further

reconditioning is necessary. If bearing surfaces are worn

or damaged, crankcase and/or closure plate will need to

be replaced.

Inspect crankshaft keyways. If worn or chipped,

replacement of crankshaft will be necessary. Inspect

crankpin for score marks or metallic pickup. Slight score

marks can be cleaned with crocus cloth soaked in oil. If

wear limits are exceeded, as stated in Specifi cations, it

will be necessary to replace crankshaft.

Remove Oil Sentry

™

System

1. Remove nut securing Oil Sentry

™

lead wire grommet

assembly in crankcase.

2. Pull grommet assembly from inside of crankcase.

3. Remove screws securing Oil Sentry

™

level switch to

crankcase. Remove switch assembly.

Remove Crankcase and Closure Plate Seals and

Bearings

NOTE: Inspect bearings for signs of wear by rotating

inner race and examine for marring or cracks.

Check to make sure race moves easily and is

not sloppy. If bearing is tight and rotates

smoothly, removal is not necessary. If you feel

any roughness or chattering or bearing is sloppy,

it should be replaced.

1. Remove oil seal from crankcase.

2. Using a suitable press, push crankshaft bearing from

crankcase.

3. Remove oil seal from closure plate.

4. Using a suitable press, push crankshaft bearing from

closure plate.

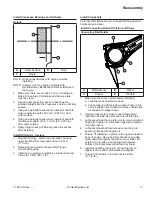

Crankcase Inspection and Service

Cylinder Bore Detail

NOTE: A 0.25 mm (0.010 in.) oversize piston is

available if resizing is selected. Initially, resize

using a boring bar, then follow procedures for

honing cylinder.

Check all gasket surfaces to make sure they are free of

gasket fragments. Gasket surfaces must also be free of

deep scratches or nicks.

Check cylinder bore for scoring. In severe cases,

unburned fuel can cause scuffi ng and scoring of cylinder

wall. It washes necessary lubricating oils off piston and

cylinder wall. As raw fuel seeps down cylinder wall,

piston rings make metal to metal contact with wall.

Scoring of cylinder wall can also be caused by localized

hot spots resulting from blocked cooling fi ns or from

inadequate or contaminated lubrication.

If cylinder bore is badly scored, excessively worn,

tapered, or out-of-round, resizing is necessary. Use an

inside micrometer to determine amount of wear (refer to

Specifi cations).

Содержание Carryall 300 2021

Страница 2: ......

Страница 16: ......

Страница 54: ...Pagination Page 4 Floor Mat BODY AND TRIM Page 4 20 2021 Carryall 300 Maintenance and Service Manual...

Страница 112: ...8 Tires WHEELS AND TIRES Figure 8 2 Inflate Tire Page 8 4 2021 Carryall 300 Maintenance and Service Manual...

Страница 118: ...Pagination Page 9 Jounce Bumpers REAR SUSPENSION Page 9 6 2021 Carryall 300 Maintenance and Service Manual...

Страница 406: ...Pagination Page 20 Snubber GASOLINE VEHICLE ENGINE Page 20 10 2021 Carryall 300 Maintenance and Service Manual...

Страница 454: ...Pagination Page 23 Driven Clutch GASOLINE VEHICLE CLUTCHES Page 23 20 2021 Carryall 300 Maintenance and Service Manual...

Страница 470: ...Pagination Page 24 Shifter Cable GASOLINE VEHICLE TRANSAXLE Page 24 16 2021 Carryall 300 Maintenance and Service Manual...

Страница 551: ...80 2018 by Kohler Co All rights reserved KohlerEngines com 17 690 15 Rev...

Страница 552: ...Pagination Page 25 Shifter Cable KOHLER ENGINE SERVICE MANUAL Page 25 2 2021 Carryall 300 Maintenance and Service Manual...

Страница 565: ...GASOLINE ENGINE HARNESS Wiring Diagrams Gasoline Engine Harness 26...

Страница 566: ...Page intentionally left blank...

Страница 567: ...GASOLINE KEY START MAIN HARNESS Wiring Diagrams Gasoline Key Start Main Harness 26...

Страница 568: ...Page intentionally left blank...

Страница 569: ...GASOLINE PEDAL START MAIN HARNESS Wiring Diagrams Gasoline Pedal Start Main Harness 26...

Страница 570: ...Page intentionally left blank...

Страница 571: ...GASOLINE INSTRUMENT PANEL HARNESS Wiring Diagrams Gasoline Instrument Panel Harness 26...

Страница 572: ...Page intentionally left blank...

Страница 573: ...GASOLINE FNR HARNESS Wiring Diagrams Gasoline FNR Harness 26...

Страница 574: ...Page intentionally left blank...

Страница 575: ...ELECTRIC MAIN HARNESS Wiring Diagrams Electric Main Harness 26...

Страница 576: ...Page intentionally left blank...

Страница 577: ...ELECTRIC INSTRUMENT PANEL HARNESS Wiring Diagrams Electric Instrument Panel Harness 26...

Страница 578: ...Page intentionally left blank...

Страница 579: ...ELECTRIC ACCESSORIES HARNESS Wiring Diagrams Electric Accessories Harness 26...

Страница 580: ...Page intentionally left blank...

Страница 588: ...NOTES...

Страница 589: ...NOTES...

Страница 590: ...NOTES...

Страница 591: ...NOTES...

Страница 592: ...NOTES...

Страница 593: ...NOTES...

Страница 594: ...NOTES...

Страница 595: ......

Страница 596: ......