25

17 690 15 Rev. --

KohlerEngines.com

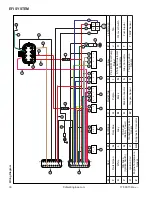

EFI SYSTEM

ECU continually performs a diagnostic check of itself,

each sensor, and system performance. If a fault is

detected, ECU can turn on a Malfunction Indicator Light

(MIL) on equipment control panel, store fault code in

its fault memory, and go into a default operating mode.

Depending on signifi cance or severity of fault, normal

operation may continue. A technician can access stored

fault code using a fault code diagnosis fl ashed out

through MIL. An optional computer software diagnostic

program is also available, refer to Tools and Aids.

ECU requires a minimum of 6.0 volts to operate.

To prevent engine over-speed and possible failure, a

rev-limiting feature is programmed into ECU. If maximum

RPM limit (4400) is exceeded, ECU suppresses injection

signals, cutting off fuel fl ow. This process repeats itself in

rapid succession, limiting operation to preset maximum.

Wiring harness used in EFI system connects electrical

components, providing current and ground paths for

system to operate. All input and output signaling occurs

through two special all weather connectors that attach

and lock to ECU. Connectors are Black and Grey and

keyed diff erently to prevent being attached to ECU

incorrectly.

Condition of wiring, connectors, and terminal

connections is essential to system function and

performance. Corrosion, moisture, and poor connections

are as likely a cause of operating problems and system

errors as an actual component. Refer to Electrical

System for additional information.

EFI system is a 12 VDC negative ground system,

designed to operate down to a minimum of 6.0 volts.

If system voltage drops below this level, operation of

voltage sensitive components such as ECU, fuel pump

relay, ignition coil, and injector will be intermittent or

disrupted, causing erratic operation or hard starting.

A fully charged, 12 volt battery with a minimum of 350

cold cranking amps is important in maintaining steady

and reliable system operation. Battery condition and

state of charge should always be checked fi rst when

troubleshooting an operational problem.

Keep in mind that EFI-related problems are often caused

by wiring harness or connections. Even small amounts

of corrosion or oxidation on terminals can interfere with

milliamp currents used in system operation.

Cleaning connectors and grounds will solve problems

in many cases. In an emergency situation, simply

disconnecting and reconnecting connectors may clean

up contacts enough to restore operation, at least

temporarily.

If a fault code indicates a problem with an electrical

component, disconnect ECU connector and test for

continuity between component connector terminals and

corresponding terminals in ECU connector using an

ohmmeter. Little or no resistance should be measured,

indicating that wiring of that particular circuit is OK.

Crankshaft position sensor is essential to engine

operation; constantly monitoring rotation and speed

(RPM) of crankshaft. There are 23 consecutive teeth

cast into fl ywheel. One tooth is missing and is used to

reference crankshaft position for ECU.

When ignition is turned ON, ECU captures and records

battery voltage. During engine start (cranking) voltage

drops 2+ volts. When ECU receives voltage drop input,

it then looks for a signal from crankshaft position sensor.

During rotation, an AC voltage pulse is created within

sensor for each passing tooth. ECU calculates engine

speed from time interval between consecutive pulses.

Gap from missing tooth creates an interrupted input

signal, corresponding to specifi c crankshaft position

near BDC for cylinder. This signal serves as a reference

for control of ignition timing by ECU. Synchronization of

inductive speed pickup and crankshaft position takes

place during fi rst two revolutions each time engine is

started. Sensor must be properly connected at all times.

If sensor becomes disconnected for any reason, engine

will quit running.

Throttle position sensor (TPS) is used to indicate throttle

plate angle to ECU. Since throttle (by way of governor)

reacts to engine load, angle of throttle plate is directly

related to load on engine.

Mounted on throttle body and operated directly off end

of throttle shaft, TPS works by varying voltage signal to

ECU in direct correlation to angle of throttle plate. This

signal, along with other sensor signals, is processed by

ECU and compared to internal preprogrammed maps to

determine required fuel and ignition settings for amount

of load.

Correct position of TPS is established and set at factory.

Do not loosen TPS or alter mounting position unless

absolutely required by fault code diagnosis. If TPS

is loosened or repositioned, appropriate TPS Learn

Procedure must be performed to re-establish baseline

relationship between ECU and TPS.

Engine temperature sensor is used by system to

help determine fuel requirements for starting (a cold

engine needs more fuel than one at or near operating

temperature).

Mounted on cylinder head, it has a temperature-sensitive

resistor. Resistance changes with engine temperature,

altering voltage sent to ECU. Using a table stored in

its memory, ECU correlates voltage drop to a specifi c

temperature. Using fuel delivery maps, ECU then

knows how much fuel is required for starting at that

temperature.

Temperature/Manifold Absolute Pressure (TMAP) sensor

is an integrated sensor that checks both intake air

temperature and manifold absolute pressure.

Intake Air Temperature control is a thermally sensitive

resistor that exhibits a change in electrical resistance

with a change in its temperature. When sensor is cold,

resistance of sensor is high. As sensor warms up,

resistance drops and voltage signal increases. From

voltage signal, ECU can determine temperature of intake

air.

Содержание Carryall 300 2021

Страница 2: ......

Страница 16: ......

Страница 54: ...Pagination Page 4 Floor Mat BODY AND TRIM Page 4 20 2021 Carryall 300 Maintenance and Service Manual...

Страница 112: ...8 Tires WHEELS AND TIRES Figure 8 2 Inflate Tire Page 8 4 2021 Carryall 300 Maintenance and Service Manual...

Страница 118: ...Pagination Page 9 Jounce Bumpers REAR SUSPENSION Page 9 6 2021 Carryall 300 Maintenance and Service Manual...

Страница 406: ...Pagination Page 20 Snubber GASOLINE VEHICLE ENGINE Page 20 10 2021 Carryall 300 Maintenance and Service Manual...

Страница 454: ...Pagination Page 23 Driven Clutch GASOLINE VEHICLE CLUTCHES Page 23 20 2021 Carryall 300 Maintenance and Service Manual...

Страница 470: ...Pagination Page 24 Shifter Cable GASOLINE VEHICLE TRANSAXLE Page 24 16 2021 Carryall 300 Maintenance and Service Manual...

Страница 551: ...80 2018 by Kohler Co All rights reserved KohlerEngines com 17 690 15 Rev...

Страница 552: ...Pagination Page 25 Shifter Cable KOHLER ENGINE SERVICE MANUAL Page 25 2 2021 Carryall 300 Maintenance and Service Manual...

Страница 565: ...GASOLINE ENGINE HARNESS Wiring Diagrams Gasoline Engine Harness 26...

Страница 566: ...Page intentionally left blank...

Страница 567: ...GASOLINE KEY START MAIN HARNESS Wiring Diagrams Gasoline Key Start Main Harness 26...

Страница 568: ...Page intentionally left blank...

Страница 569: ...GASOLINE PEDAL START MAIN HARNESS Wiring Diagrams Gasoline Pedal Start Main Harness 26...

Страница 570: ...Page intentionally left blank...

Страница 571: ...GASOLINE INSTRUMENT PANEL HARNESS Wiring Diagrams Gasoline Instrument Panel Harness 26...

Страница 572: ...Page intentionally left blank...

Страница 573: ...GASOLINE FNR HARNESS Wiring Diagrams Gasoline FNR Harness 26...

Страница 574: ...Page intentionally left blank...

Страница 575: ...ELECTRIC MAIN HARNESS Wiring Diagrams Electric Main Harness 26...

Страница 576: ...Page intentionally left blank...

Страница 577: ...ELECTRIC INSTRUMENT PANEL HARNESS Wiring Diagrams Electric Instrument Panel Harness 26...

Страница 578: ...Page intentionally left blank...

Страница 579: ...ELECTRIC ACCESSORIES HARNESS Wiring Diagrams Electric Accessories Harness 26...

Страница 580: ...Page intentionally left blank...

Страница 588: ...NOTES...

Страница 589: ...NOTES...

Страница 590: ...NOTES...

Страница 591: ...NOTES...

Страница 592: ...NOTES...

Страница 593: ...NOTES...

Страница 594: ...NOTES...

Страница 595: ......

Страница 596: ......