41

17 690 15 Rev. --

KohlerEngines.com

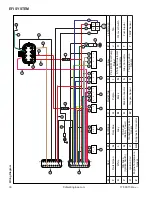

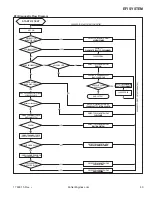

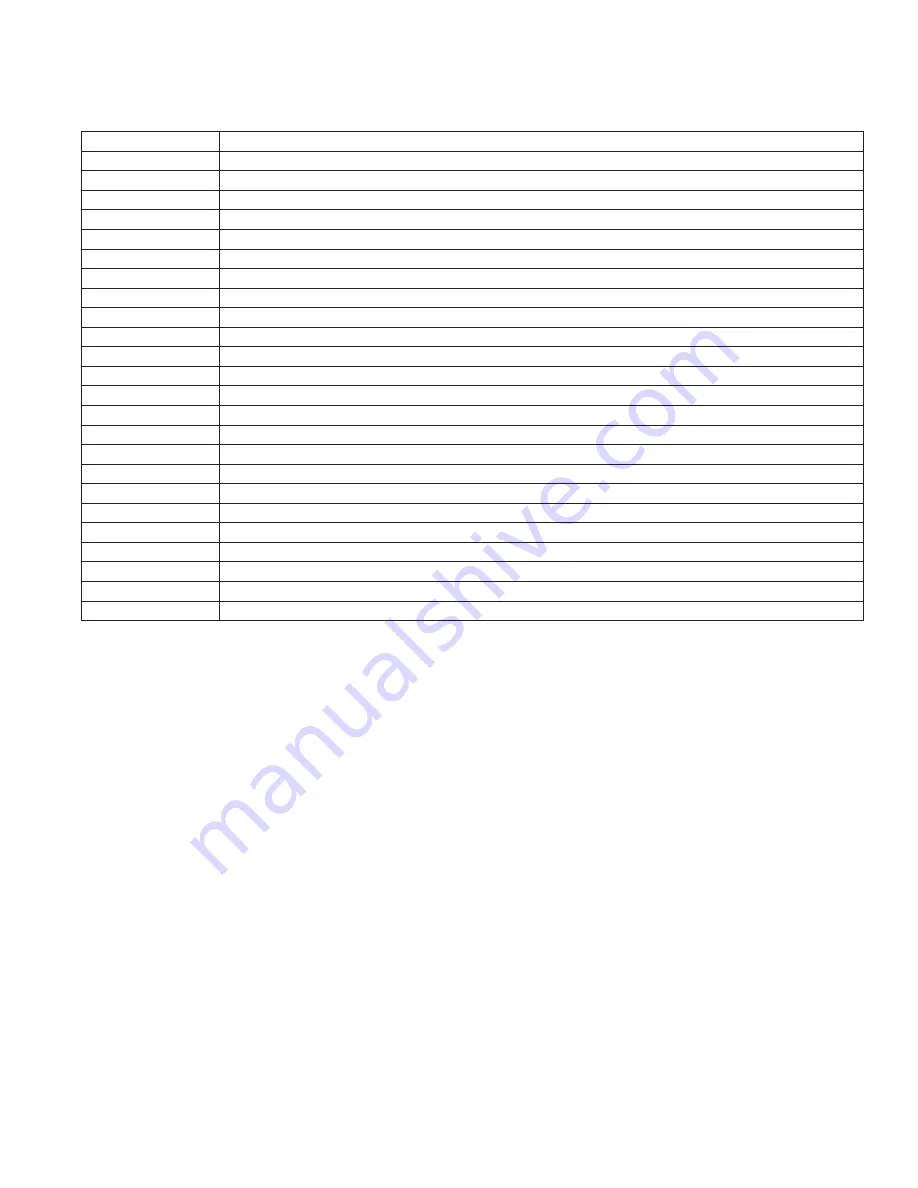

EFI SYSTEM

Diagnostic Fault Code Summary

Fault Code

Connection or Failure Description

0031

Oxygen Sensor Heater Circuit Low Voltage

0032

Oxygen Sensor Heater Circuit High Voltage

0107

Manifold Absolute Pressure (TMAP) Circuit Low Voltage or Open

0108

Manifold Absolute Pressure (TMAP) Circuit High Voltage

0112

Intake Air Temperature (TMAP) Circuit Low Voltage

0113

Intake Air Temperature (TMAP) Circuit High Voltage or Open

0117

Engine Temperature Sensor Circuit Low Voltage

0118

Engine Temperature Sensor Circuit High Voltage or Open

0122

Throttle Position Sensor Circuit Low Voltage or Open

0123

Throttle Position Sensor Circuit High Voltage

0131

Oxygen Sensor 1 Circuit Low Voltage, or Open

0132

Oxygen Sensor 1 Circuit High Voltage

0171

Maximum Adaptation Limit Exceeded

0172

Minimum Adaptation Limit Exceeded

0174

Lean Fuel Condition at High Load (Open Loop)

0201

Injector Circuit Malfunction

0230

Fuel Pump Relay Circuit Low Voltage or Open

0232

Fuel Pump Relay Circuit High Voltage

0336

Crankshaft Position Sensor Noisy Signal

0337

Crankshaft Position Sensor No Signal

0351

Ignition Coil Malfunction

0562

System Voltage Low

0563

System Voltage High

0650

MIL Circuit Malfunction

61

End of Code Transmission

MIL Operation for Pedal Start Applications

Key ON/MIL on for 3 seconds then turns off . MIL will

remain off during normal operation or until a trouble

code/fault is detected or until key switch is cycled power

OFF for 15 seconds and returned to key ON position.

If code/fault is detected and is a current code, light will

remain on for duration of operating cycle (key ON). If

code/fault is temporarily detected and fault is recorded

and then returns to normal, MIL will go out, but code is

stored in ECU as a historic code.

MIL Operation for Key Start Applications

ECU continuously monitors engine operation against

preset performance limits. If operation is outside limits,

ECU activates MIL, if equipped, and stores a diagnostic

code in its fault memory. If component or system

returns to proper function, ECU will turn off MIL. If MIL

stays illuminated, it warns customer a fault is currently

happening, and dealer service is required. Upon receipt,

dealer technician can access fault code(s) to help

determine what portion of system is malfunctioning.

Codes are accessed through key switch and displayed

as blinks or fl ashes of MIL. Access codes as follows:

1. Check that battery voltage is above 11 volts.

2. Start with key switch OFF.

3. Turn key switch to ON and OFF, then ON and OFF,

then ON, leaving it on in third sequence. Do not start

engine. Time between sequences must be less than

2.5 seconds.

4. MIL will blink a series of times. Number of times MIL

blinks represents a number in fault code.

5. A sequence of four digits make up a fault code.

There is a one (1) second pause between blinks of a

fault code. There is a three (3) second pause

between separate fault codes. After fault code(s) are

blinked a two digit 61 is blinked to indicate program

has completed. Zero (0) = ten (10) blinks.

a. It’s a good idea to write down codes as they

appear, as they may not be in numerical

sequence.

b. Code 61 will always be last code displayed,

indicating end of code transmission. If code 61

appears immediately, no other fault codes are

present.

After problem has been corrected, fault codes may

be cleared by following ECU Reset and TPS Learn

Procedures.

Diagnostic Fault Code Summary lists fault codes, and

what they correspond to. Diagnostic Code Summary

is a list of individual codes with an explanation of what

triggers them, what symptoms might be expected, and

probable causes.

Содержание Carryall 300 2021

Страница 2: ......

Страница 16: ......

Страница 54: ...Pagination Page 4 Floor Mat BODY AND TRIM Page 4 20 2021 Carryall 300 Maintenance and Service Manual...

Страница 112: ...8 Tires WHEELS AND TIRES Figure 8 2 Inflate Tire Page 8 4 2021 Carryall 300 Maintenance and Service Manual...

Страница 118: ...Pagination Page 9 Jounce Bumpers REAR SUSPENSION Page 9 6 2021 Carryall 300 Maintenance and Service Manual...

Страница 406: ...Pagination Page 20 Snubber GASOLINE VEHICLE ENGINE Page 20 10 2021 Carryall 300 Maintenance and Service Manual...

Страница 454: ...Pagination Page 23 Driven Clutch GASOLINE VEHICLE CLUTCHES Page 23 20 2021 Carryall 300 Maintenance and Service Manual...

Страница 470: ...Pagination Page 24 Shifter Cable GASOLINE VEHICLE TRANSAXLE Page 24 16 2021 Carryall 300 Maintenance and Service Manual...

Страница 551: ...80 2018 by Kohler Co All rights reserved KohlerEngines com 17 690 15 Rev...

Страница 552: ...Pagination Page 25 Shifter Cable KOHLER ENGINE SERVICE MANUAL Page 25 2 2021 Carryall 300 Maintenance and Service Manual...

Страница 565: ...GASOLINE ENGINE HARNESS Wiring Diagrams Gasoline Engine Harness 26...

Страница 566: ...Page intentionally left blank...

Страница 567: ...GASOLINE KEY START MAIN HARNESS Wiring Diagrams Gasoline Key Start Main Harness 26...

Страница 568: ...Page intentionally left blank...

Страница 569: ...GASOLINE PEDAL START MAIN HARNESS Wiring Diagrams Gasoline Pedal Start Main Harness 26...

Страница 570: ...Page intentionally left blank...

Страница 571: ...GASOLINE INSTRUMENT PANEL HARNESS Wiring Diagrams Gasoline Instrument Panel Harness 26...

Страница 572: ...Page intentionally left blank...

Страница 573: ...GASOLINE FNR HARNESS Wiring Diagrams Gasoline FNR Harness 26...

Страница 574: ...Page intentionally left blank...

Страница 575: ...ELECTRIC MAIN HARNESS Wiring Diagrams Electric Main Harness 26...

Страница 576: ...Page intentionally left blank...

Страница 577: ...ELECTRIC INSTRUMENT PANEL HARNESS Wiring Diagrams Electric Instrument Panel Harness 26...

Страница 578: ...Page intentionally left blank...

Страница 579: ...ELECTRIC ACCESSORIES HARNESS Wiring Diagrams Electric Accessories Harness 26...

Страница 580: ...Page intentionally left blank...

Страница 588: ...NOTES...

Страница 589: ...NOTES...

Страница 590: ...NOTES...

Страница 591: ...NOTES...

Страница 592: ...NOTES...

Страница 593: ...NOTES...

Страница 594: ...NOTES...

Страница 595: ......

Страница 596: ......