CLASSIC BLAST MACHINE with TLR-100/300 REMOTE CONTROLS

Page 22

© 2018 CLEMCO INDUSTRIES CORP.

www.clemcoindustries.com

Manual No. 22501, Rev. I 02/18

6.5.1

All service on the outlet valve must be done with

the air OFF and the air supply locked out and tagged

out. It is not necessary to remove the valve from the

blast machine.

6.5.2

Remove the cap by unscrewing the four cap

screws.

6.5.3

Remove the diaphragm and inspect it for

damage. Replace as necessary.

6.5.4

Inspect the seat in the body. If worn, replace the

body.

6.5.5

Reassemble in reverse order.

6.6

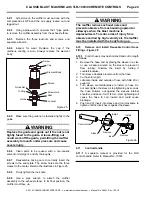

Abrasive Trap - Figure 21

WARNING

To avoid serious injury from the sudden release

of compressed air, all service on the blast

machine must be done with the air OFF and the

air supply locked out and tagged out and the air-

supply line bled.

NOTE: Failure to clean the abrasive trap on a regular

basis is a major cause of system malfunction. Clean

abrasive-trap screen and empty the trap at least twice

daily.

6.6.1

To check the abrasive-trap screen, loosen the

thumb screw on the upper lock bar, swing the lock bar

off the cap, and remove the cap.

6.6.2

Remove the screen and inspect it for wear and

blockage. Replace it when it is clogged or worn. Keep

spare screens on hand. Do not install the screen in the

trap until the bottom section of the trap is cleaned per

the following instructions.

6.6.3

To clean the bottom section of the trap, loosen

the thumb screw on the lower lock bar, swing the lock

bar off the lower cap, and then remove the cap.

6.6.4

Empty all abrasive from the bottom and top

sections.

6.6.5

Install the screen in the top section. The smaller

diameter end of the screen must face up as shown in

Figure 21.

6.6.6

Reassemble the upper and lower caps. NOTE:

The upper and lower caps are identical except the

screen gasket is glued into the upper cap.

Make sure

the screen gasket is in place in the upper cap and

the O-rings are in place on both caps before

assembly.

SCR

E E N

L

C

O

EA N

UT

*Make sure the screen gasket is in the upper cap.

Figure

21

6.7.

Replacing the Pop-Up Valve - Figure 22

WARNING

To avoid serious injury from the sudden release

of compressed air, all service on the blast

machine must be done with the machine

depressurized, the air OFF, the air supply locked

out and tagged out, and the air-supply line bled.

6.7.1

To gain access to the pop-up valve, loosen the

nut on the clamp and remove the clamp and inspection

door.

6.7.2

Using a small pipe wrench, unscrew the pop-up

valve guide by turning it counterclockwise. Remove the

pop-up valve and guide from the machine.

6.7.3

While the pop-up valve is out, check alignment

as follows: Screw a 1-1/4" nipple that is at least 12" long

into the elbow in place of the pop-up guide. Check the

alignment through the pop-up filling port. The nipple

should be close to the center of the port. If it is not,

adjust the horizontal pipe. A misaligned pop-up valve

Upper Cap

Upper Lock Bar

Thumb Screw

Lower Lock Bar

Cap O-Ring

*Screen Gasket

Lower Cap

Cap O-Ring

Screen

Small end of

screen faces up.