CLASSIC BLAST MACHINE with TLR-100/300 REMOTE CONTROLS

Page 24

© 2018 CLEMCO INDUSTRIES CORP.

www.clemcoindustries.com

Manual No. 22501, Rev. I 02/18

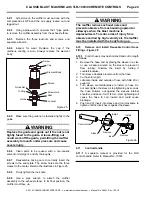

6.9.1

All service on the muffler must be done with the

compressed air OFF and the air supply locked out and

tagged out.

6.9.2

Using a pipe wrench, unscrew the 1" pipe guide,

to remove the muffler assembly from the exhaust elbow.

6.9.3

Remove the three locknuts and screws, and

separate all parts.

6.9.4

Inspect for wear. Replace the cap if the

urethane coating is worn. Always replace the element

body.

Figure

25

6.9.5

Make sure the guide nut is fastened tightly to the

guide.

WARNING

Replace the guide and guide nut if the nut is not

tightly fused to the guide. A loose-fitting nut

could work off the guide, permitting the muffler

assembly to launch under pressure and cause

severe injury.

6.9.6

Clean parts to be reused, with a non-caustic

solvent or detergent, and dry thoroughly.

6.9.7

Reassemble, taking care to correctly insert the

screws in the seat plate. The screw holes are the three

closest to the center. Refer to the illustration in Figure 25.

6.9.8

Firmly tighten the lock nuts.

6.9.9

Use a pipe wrench to attach the muffler

assembly to the exhaust elbow. In its final position, the

muffler must face up.

WARNING

The muffler reduces exhaust noise and

prevents abrasive from exhausting upward or

sideways when the blast machine is

depressurized. To reduce risk of injury from

abrasive carried by high velocity air, the muffler

must be installed with the body facing up.

6.10

Remove and Install Reusable Control Hose

Fittings - Figure 26

6.10.1

Control hoses may be shortened and cut to length

as follows:

1. Remove the hose end by placing the sleeve in a vise

or use a backup wrench on the sleeve to prevent it

from turning. Unscrew the insert by turning it

counterclockwise.

2. Turn sleeve clockwise to remove from the hose.

3. Cut hose to length.

4. Lubricate inside and outside of hose with SAE 20 or

equal oil.

5. Turn sleeve counterclockwise to install on hose. Do

not over tighten the sleeve; stop tightening as soon as

the hose bottoms out against the sleeves internal

shoulder, and back it out 1/4 turn. Over tightening will

cause the hose to curl inward and could cause

blockage.

6. Push end of insert into sleeve and turn clockwise to

tighten until the insert hex is against the sleeve.

Figure

26

6.11 Control

Handle

6.11.1

A separate manual is provided for the RLX

control handle. Refer to Manual No. 10574.

Locknut

Sleeve

Insert

Control Hose

Install

Remove

Install

Remove

Element Body

Cap

Screw

Guide

Seat

Guide Nut

O-Ring

Screw Hole

Screen