CLASSIC BLAST MACHINE with TLR-100/300 REMOTE CONTROLS

Page 14

© 2018 CLEMCO INDUSTRIES CORP.

www.clemcoindustries.com

Manual No. 22501, Rev. I 02/18

3.5

Operation and Function of the Choke Valve

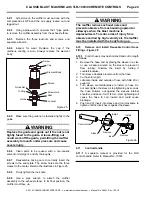

Figure 14

3.5.1

Always fully open the choke valve while blasting;

open is when the handle is vertical and aligned with the

piping as shown in Figure 14.

Figure

14

3.5.2

Closing the choke valve while blasting lowers

pressure in the pusher line from the pressure in the

vessel. Closing the valve forces abrasive through the

metering valve to clear minor blockage, such as damp

abrasive, or is used to rapidly empty the machine at the

end of the day.

NOTICE

Do not blast with choke valve closed or partially

closed. Prolonged blasting with the choke valve

partially closed will accelerate wear on the

metering valve.

3.6

Operation of the Optional Abrasive Cutoff

Switch (ACS) - Figure 15

3.6.1

The ACS closes the metering valve so that air

alone without abrasive exits the nozzle. Common uses

for this feature are:

1. Clearing abrasive from the blast hose when blasting

is finished. This is helpful in a lot of applications and

necessary when the blast hose is vertical to prevent

abrasive from collecting in low spots in the blast hose,

eliminating excessive abrasive slugging at startup.

2. Blowing abrasive off the blasted surface. Note:

Small amounts of residual abrasive may exit the nozzle

with the air, requiring blowing off or otherwise cleaning

surface outside the blasting area prior to painting.

3. When wet blasting with an injector or wetblast

attachment, it is used to assist in drying the surface after

it is washed down.

WARNING

OSHA sets exposure limits for people and the

environment. Airborne dust can increase the

exposure levels beyond permissible limits. OSHA

prohibits blowing with compressed air as a cleaning

method for lead-based paint dust or other hazardous

dust, unless the compressed air is used in

conjunction with a ventilation system designed to

capture the volume of airborne dust created by the

compressed air, 29 CFR 1926 (h). The ACS is for

blowing off abrasive from a blasted surface, NOT for

general area cleanup.

3.6.2

The abrasive cutoff switch is situated directly

behind the control handle. The switch may be flipped

open or closed at any time, but will not operate the

metering valve unless the control handle is pressed.

3.6.2.1 Blast Mode:

Moving the ACS toggle away from

the nozzle to the ON (CYL port) position sends control

air to the abrasive metering valve opens the valve so that

the blast machine operates normally with air and abrasive

coming out the nozzle.

Figure

15

3.6.2.2

Blowdown

Mode:

Moving the ACS toggle toward

the nozzle to the OFF position cuts off the control air to the

abrasive metering valve, closes the valve, and stops the

abrasive flow. This action allows air alone to exit the

nozzle, useful for clearing the blast hose before shutting

down, and blowing abrasive and water off the blasted

surface.

3.7 Stop

Blasting

3.7.1

To stop blasting, release the control handle

lever. The inlet valve closes, the outlet valve opens, and

the blast machine depressurizes. The pop-up valve

Choke Valve

Valve is shown open;

handle position is

aligned with the piping.

Blast Mode

Toggle pointing away from nozzle.

Blowdown Mode

Toggle pointing toward nozzle.

ON

OFF