CLASSIC BLAST MACHINE with TLR-100/300 REMOTE CONTROLS

Page 11

© 2018 CLEMCO INDUSTRIES CORP.

www.clemcoindustries.com

Manual No. 22501, Rev. I 02/18

WARNING

Hose disconnection while under pressure can

cause serious injury or death. Use safety lock-

pins or safety wire to lock twist-on (claw-type)

couplings together and prevent accidental

separation while under pressure, and use

safety cables to prevent hose from whipping

should separation occur.

3.2.5

Attach the ends of the 50-foot twinline hose to

the unions previously connected to the 5-foot twinline

hose. Either side of the hose can be attached to either

fitting.

3.2.6

Check all fittings to make sure they are wrench-

tight. Leaks will cause the system to malfunction.

3.2.7

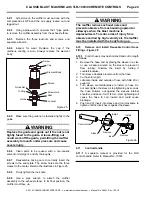

Make sure the choke valve is open; the valve is

open when the handle position is aligned with the piping,

as shown in Figure 10.

3.2.8

Close the abrasive metering valve. The FSV and

LPV (Lo-Pot valve) are closed when the handle is all the

way to either side of center; refer to Section 4.1. The

alternate MPV manual pinch-tube metering valve and

Quantum metering valves are closed when the metering

knob is turned fully clockwise. Manuals are provided with

alternate metering valves. NOTE: it is not necessary to

close the metering valve after the initial startup and

adjustment per Section 4.1.

Compressed-Air and Abrasive Consumption

Consumption rates are based on abrasives that weigh 100 pounds per cubic foot

Nozzle

Pressure at the Nozzle (psi)

Air, Power,

Orifice

and Abrasive

Size (in.)

50

60

70

80

90

100

125

140

Requirements

26

30 33 38 41 45 55 61

Air

(cfm)

No.

3 150

171 196 216 238 264 319 353 Abrasive

(lbs/hr)

3/16" 6

7 8 9

10

10

12

14

Compressor

(hp)

47

54 61 68 74 81 98

108

Air

(cfm)

No.

4 268

312 354 408 448 494 608 676 Abrasive

(lbs/hr)

1/4" 11

12 14 16 17 18 22 24

Compressor

(hp)

77 89 101 113 126 137 168 186 Air

(cfm)

No.

5 468

534 604 672 740 812 982

1085 Abrasive

(lbs/hr)

5/16" 18

20 23 26 28 31 37 42

Compressor

(hp)

108

126 143 161 173 196 237 263 Air

(cfm)

No.

6 668

764 864 960

1052

1152

1393

1538 Abrasive

(lbs/hr)

3/8" 24

28 32 36 39 44 52 59

Compressor

(hp)

147

170 194 217 240 254 314 347 Air

(cfm)

No.

7 896

1032 1176 1312 1448 1584 1931 2138 Abrasive

(lbs/hr)

7/16" 33

38 44 49 54 57 69 77

Compressor

(hp)

195

224 252 280 309 338 409 452 Air

(cfm)

No.

8 1160

1336 1512 1680 1856 2024 2459 2718 Abrasive

(lbs/hr)

1/2" 44

50 56 63 69 75 90

101

Compressor

(hp)

For nozzle sizes 3/8" to 1/2", blast machines should be equipped with 1-1/4" or larger piping and inlet valve to prevent

pressure loss.

Air requirements were measured by a flowmeter under actual blasting conditions and are, therefore, lower than figures for

air alone, with no abrasive.

Horsepower requirements are based on 4.5 cfm per horsepower.

Figures are for reference only and may vary for different working conditions. Several variables, including metering valve

adjustments, can affect abrasive flow.

Figures show approximate compressed air and abrasive consumption when nozzles are new. Consumption will increase as

the nozzle wears.

Figure 10