CLASSIC BLAST MACHINE with TLR-100/300 REMOTE CONTROLS

Page 21

© 2018 CLEMCO INDUSTRIES CORP.

www.clemcoindustries.com

Manual No. 22501, Rev. I 02/18

6.4.4

To remove the bonnet, lift it straight up until the

piston rod clears the spindle guide.

6.4.5

Remove the spindle, plug assembly, and spring

from the valve body.

6.4.6

Remove the piston from the bonnet by pulling

the piston rod.

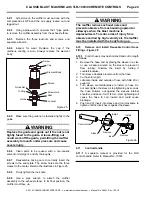

Figure

19

6.4.7

Inspect all parts for wear and damage as

follows:

Inspect the valve-plug washer, valve plug, and plug

retainer for damage. Replace all damaged parts.

When reassembling the valve-plug assembly tighten

the retainer enough to compress the washer, but not

so tight that it causes it to bulge.

Examine the body casting for wear. If the body or the

machined seat is worn, replace the body.

Examine the spring guide bolt and nylon washer. If

either is worn, replace both.

The spring is approximately 1-5/8

long; if it is

abrasive worn, rusty, or compressed, replace it.

The piston cup should fit snugly against the bonnet’s

cylinder wall. If it does not, replace the piston

assembly.

The piston rod should be free of deep abrasion and

move freely in the spindle guide’s bore. If it is badly

abraded, drags in the bore, or is loose in the bore,

replace the piston assembly.

6.4.8

Lubricate the cylinder wall and piston cup with

lightweight machine oil or tool oil.

6.4.9

Install the piston into the bonnet’s cylinder.

Cocking the piston so it enters the bonnet at a slight

angle and rotating it while applying pressure makes

assembly easier. Do not push the piston fully into the

bonnet; the rod should be flush with the opening.

6.4.10

Place the spring over the guide bolt and place

the plug assembly (retainer down) on the spring.

6.4.11

Place the spindle in the body. The large opening

faces down and fits over the plug fins. The spindle

shoulder will not rest on the valve body due to the force

of the spring.

6.4.12

To assemble the bonnet to the valve body, first

insert the piston rod into the spindle guide hole. While

keeping the bonnet, spindle, and body aligned, screw the

bonnet onto the body. If all parts are correctly aligned, the

body will screw on hand-tight until it is seated.

NOTE: If

the bonnet does not screw on hand-tight, do not

force it. Recheck alignment and repeat assembly.

6.4.13

After the bonnet is fully seated on the body,

tighten the assembly with a wrench.

6.4.14

Attach the control hose to the fitting on the

bonnet.

6.5

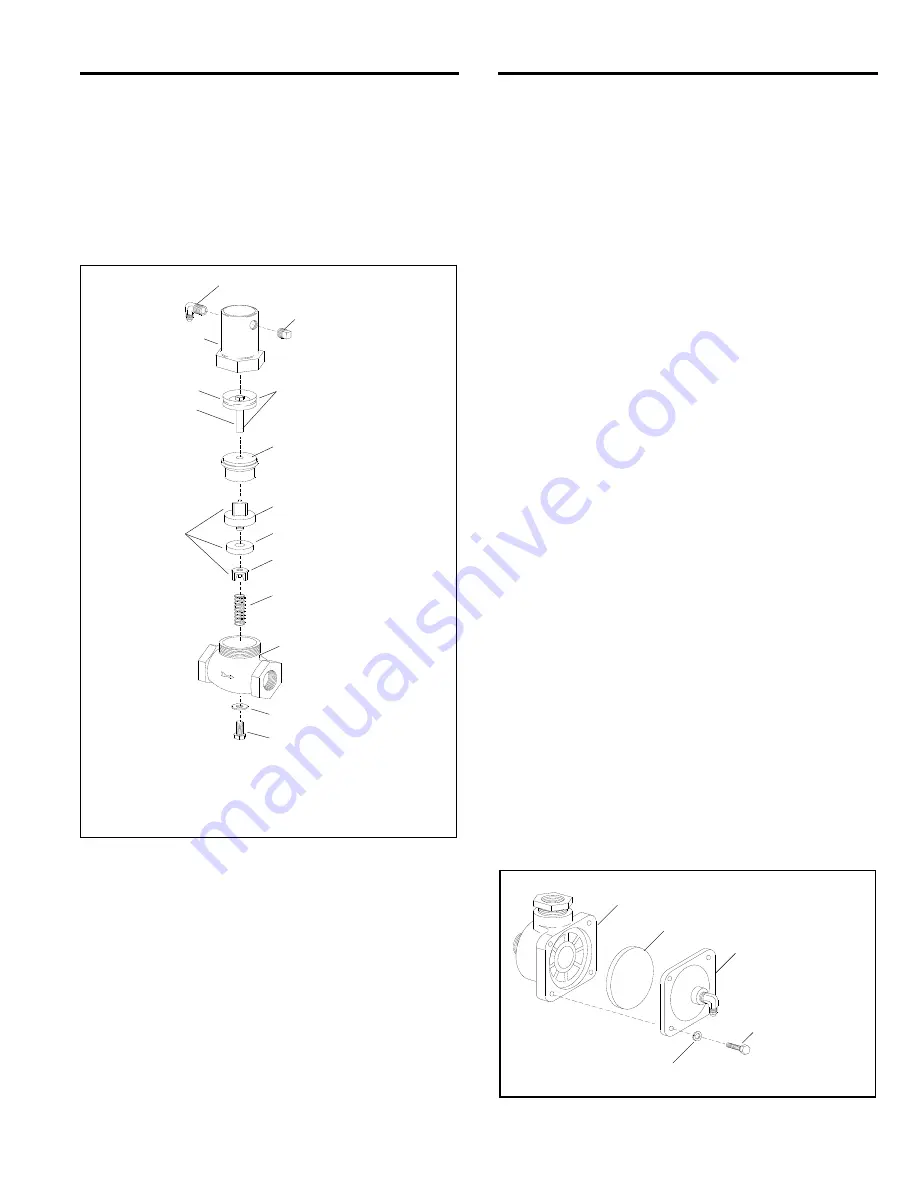

Diaphragm Outlet Valve - Figure 20

Refer to Section 6.4 to service the piston outlet valve.

Figure

20

*Items included in service kit.

For replacement parts, refer to Section 8.11.

Valve Body

Diaphragm

Cap

Cap Screw

Lock Washer

1/4-NPT Plug

Elbow Adaptor

Valve Bonnet

Plug and Spindle Guide

Piston Assembly

Piston Cup

*Valve Plug

Piston Rod

*Valve Plug

*Valve-Plug Retainer

*Spring

Valve Body

*Nylon Washer

*Cap Screw (Guide Bolt)

Plug

Assembly