11

CLASSIC EDGE OUTDOOR FURNACE • OWNER'S MANUAL

Following are some reasons that green, unseasoned wood should not be used:

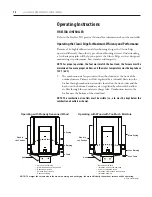

• Green wood contains about 50% moisture by weight. Energy is

required to heat the wood and evaporate the moisture - energy which

could have been used to provide heat for the home. The illustration

below shows that burning drier, seasoned wood provides more energy

for heating your home compared with burning green, unseasoned

wood that uses more energy to evaporate the moisture and provides

less energy for heating your home.

• Unseasoned wood provides less heat, resulting in more condensates

(moisture) in the firebox and increased wood consumption.

• Increased moisture in the firebox can result in corrosion.

• Unseasoned wood causes reduced performance, lower combustion

rates and lower heat output.

• The full heating potential is unlikely to be achieved with unseasoned

wood.

• Burning wood with an excessively high moisture content increases

maintenance requirements and can lower the service life of the outdoor

furnace.

• The higher the moisture content of the wood being burned, the harder

it is to maintain a glowing coal bed because it burns more slowly.

NOTE: Do not store wood within the outdoor furnace installation clearances or within the

spaces required for fueling, ash removal and other routine maintenance operations.

Importance of Properly Seasoned Wood

Burning properly seasoned wood (less than 25% moisture content) will

minimize wood usage and maximize the efficiency and performance of the

Classic Edge (see Wood Selection and Preparation in the Introduction).

In order for wood to burn, the moisture in the wood must first be evaporated

(boiled off). The more moisture there is in the wood, the more energy it will

consume to dry it and the less energy will be available for heating the water.

As shown, the higher the moisture in the wood, the larger the volume of the

firebox that is used for drying and the smaller the volume used for burning.

This results in lower efficiency and lower heat output.

The lower the moisture in the wood, the smaller the volume of the firebox that

is used for drying and the larger the volume used for burning. This results in

higher efficiency and higher heat output.