2–9

62-11640

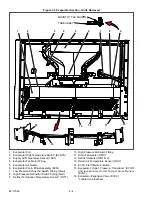

f. Supply Air Temperature Sensor (1SAT)

The 1SAT is a thermistor type temperature control probe

which provides the control system with information on

the temperature of the air leaving the evaporator sec-

tion. The reading is displayed, recorded in the DataLink

data recorder and used to control the refrigeration sys-

tem. It is located in the supply air outlet housing.

2.5

SYSTEM OPERATING CONTROLS AND COM-

PONENTS

Temperature control is provided by the Carrier Transi-

cold APX™ Control System. Once the system is set at

the desired temperature, the unit will operate automati-

cally to maintain the desired temperature within very

close limits.

2.5.1

Automatic Start-Stop

Standard equipment includes an auto start-stop fea-

ture. This feature provides automatic cycling of the die-

sel engine or compressor, which in turn offers an

energy efficient alternative to continuous operation of

the system with control of temperature accomplished

by alternate cooling and heating of the supply air

(evaporator outlet air).

2.5.2

Special Features

The following additional special features are incorpo-

rated into the Carrier Transicold APX control system:

• An easy to read LCD display MessageCenter

which clearly displays all required information

• Unit Data and Advanced User selectable Func-

tional Parameters

• Programmable Maintenance Hour Meters

• Bright LED Alarm Light

• Fully Automated Pretrip

• Automated control system Self-test

• DataLink data recorder (uses System date and

time)

• Trip Start to record date/time of trip in DataLink

data recorder memory

• USB communication for downloading data,

upgrading operational software, and Configura-

tion set up

• Automatic Engine Starting

• Functional Parameter locks

• Alarms are stored in control system memory for

future reference

• “ATM style” menu system (which reduces key-

strokes)

• “Dashboard” display screens which display up to

5 data points simultaneously

• Backlit “Carrier Blue” silicone keypad makes

operation easy for drivers

2.5.3

Component Description and Location

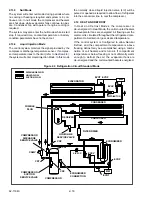

The APX control system is an automotive style, decen-

tralized, modular system with CAN bus (Controlled

Area Network) connectivity. Hardware associated with

the system includes:

• power control module (PCM,

• main microprocessor module (MM)

• stepper valve module (SVM)

• engine control unit (ENCU)

• standby and control boxes (

• control

−

box

−

mounted overload ground fault

module (OGF,

)

• control

−

box

−

mounted contactor control boards

)

• display module (DM,

NOTICE

Under no circumstances should anyone

attempt to repair sealed module internal

components. Should a problem develop

with these components, contact your

nearest Carrier Transicold dealer for

replacement.

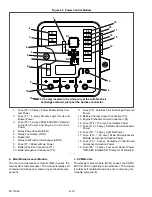

a. Power Control Module

The power control module (PCM - see

) is

responsible for distribution of power from the battery to

the system components, when starting, and then from

the battery charger to the system components and to

the battery (for charging) once power is available.

The module houses the system relays, low voltage

fuses and the DC current transformer (CT1). The cur-

rent transformer provides a reading of the total 12 VDC

system current draw (amps) to the main microproces-

sor at terminal 2MM12 (see schematic diagram,

Содержание Vector 8500

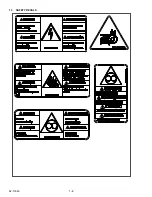

Страница 23: ...62 11640 1 6 1 3 SAFETY DECALS ...

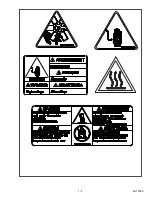

Страница 24: ...1 7 62 11640 62 03958 ...

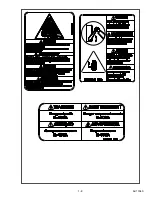

Страница 25: ...62 11640 1 8 ...

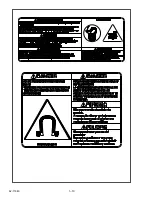

Страница 26: ...1 9 62 11640 ...

Страница 27: ...62 11640 1 10 ...

Страница 125: ...62 11640 SECTION 6 MESSAGECENTER PARAGRAPH NUMBER Page 6 1 MESSAGECENTER MESSAGES 6 1 ...

Страница 321: ......

Страница 322: ......