62-11640

8–24

Due to the “washing” action of normal defrost the fiber

dust and particles may not be visible on the face of the

coil but may accumulate deep within.

Clean the evaporator coil on a regular basis, not only to

remove cardboard dust, but to remove any grease or

oil film which sometimes coats the fins and prevents

water from draining into the drain pan.

Cardboard fiber particles after being wetted and dried

several times can be very hard to remove. Therefore,

several washings may be necessary.

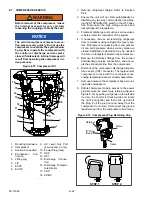

1. Ensure the unit will not start automatically by

disabling any two way communication and plac-

ing the STOP/RUN-OFF switch in the OFF posi-

tion. Disconnect the high voltage source and

lockout/tagout the receptacle.

2. Remove rubber check valves (Kazoo) from drain

lines of the evaporator to be cleaned.

3. Spray coil with a mild detergent solution such as

Oakite 164 or 202) or any good commercial

grade automatic dish washer detergent such as

Electrosol or Cascade and let the solution stand

for a few minutes and reverse flush (opposite

normal air flow) with clean water at mild pres-

sure. A garden hose with spray nozzle is usually

sufficient. Make sure drain lines are clean.

4. Re-install check valves and run unit until Defrost

Mode can be initiated to check for proper drain-

ing from drain pan.

8.8.2

Condenser Coil

a. Cleaning

NOTE

Only clean water should be used to wash the

condenser coil. Do not use any detergents to

clean the condenser.

Remove all foreign material from the condenser coil by

reversing the normal air flow. (Air is pulled in through

the front and discharges over the engine.) Compressed

air or water may be used as a cleaning agent. Take

care so that the fins aren’t bent during this procedure.

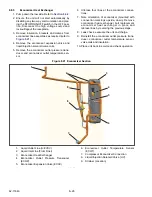

b. Condenser Coil Replacement

1. Remove the refrigerant charge. Refer to

NOTE

If the condenser coil (

) requires

replacement, the entire condenser/radiator

assembly must be removed from the unit

and disassembled/reassembled on the

bench.

2. Drain coolant into a suitable container by remov-

ing coolant bottle cap and then the engine drain

plug.

3. Remove the surround with the grille attached.

Refer to

4. Remove hoses from radiator.

NOTICE

Unit uses R404A and POE oil. The use of

inert gas brazing procedures is manda-

tory for all Carrier Transicold refrigera-

tion units; otherwise compressor failure

will occur. For more information Refer to

Technical Procedure 98-50553-00 Inert

Gas Brazing.

5. Unbraze refrigerant lines from condenser coil.

6. Disconnect the hail and bug screen sufficient to

reach the ambient sensor and wiring. Remove

sensor and wiring from radiator frame.

7. Remove the eight bolts securing the condenser/

radiator assembly to the unit.

8. Remove the condenser/radiator assembly from

the unit.

9. Remove the eight bolts securing the radiator

frame to the condenser frame and set radiator

frame aside.

10. Separate the radiator from the condenser/radia-

tor assembly by removing the top and bottom

radiator mounting brackets. Set radiator aside.

11. Remove condenser coil by removing the con-

denser coil mounting brackets.

12. Reassemble condenser/radiator assembly in

reverse order using new coil.

NOTICE

Do not bend the copper tubing on the

condenser coil when installing the new

condenser. Bend the unit tubing if tubes

do not align correctly.

NOTE

Before applying heat to the new condenser

apply a wet rag to the entire copper to alumi-

num transition area to avoid melting the pro-

tective heat shrink or damaging the joint.

13. Reassemble condenser/radiator assembly into

unit.

14. Leak check, evacuate and charge the system.

Refer to

&

.

15. Refill engine coolant. Refer to

Содержание Vector 8500

Страница 23: ...62 11640 1 6 1 3 SAFETY DECALS ...

Страница 24: ...1 7 62 11640 62 03958 ...

Страница 25: ...62 11640 1 8 ...

Страница 26: ...1 9 62 11640 ...

Страница 27: ...62 11640 1 10 ...

Страница 125: ...62 11640 SECTION 6 MESSAGECENTER PARAGRAPH NUMBER Page 6 1 MESSAGECENTER MESSAGES 6 1 ...

Страница 321: ......

Страница 322: ......