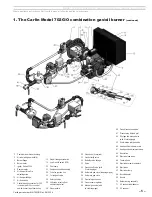

Model 702G/O Advanced gas/oil burners — Instruction manual

Carlin part number MN702GO Rev. 06/23/14

– 3 –

Where appliance instructions differ from this manual, follow the appliance instructions.

Burner applications

Follow all instructions in this manual, the primary control data sheet and

the appliance manual.

Verify the burner is correct for the appliance being used and for all ap-

plicable codes/standards.

Adjust the nozzle selection/firing rate if necessary due to positive overfire

pressure and/or altitudes more than 2,000 feet above sea level. See the

NOTICE under the Ratings information at right. Where appliance appli-

cation information is available, the recommended firing rate and burner

information will include appropriate adjustments for positive overfire

pressure and recommendations for high altitudes. Follow the appliance

manual guidelines when available.

Damage or shortage claims

The consignee of the shipment must file damage or shortage claims

immediately against the transportation company. See the NOTICE on

page 1 for burner carton information.

When calling or writing about the

burner:

Please provide us with the UL serial number and burner model number

to assist us in locating information. This information can be helpful when

troubleshooting or obtaining replacement parts.

Codes and standards

Certification

702G/O burners are U.L. listed for the U.S., certified to comply with:

•

ANSI/UL 296, for use with #1 or #2 heating oil (per standard ASTM D396).

•

UL 795, for use with natural gas or propane.

•

Burner labels list compliance, when required, with special local, state

or provincial approvals.

Install this burner in accordance with all local codes and

authorities having jurisdiction. Regulations of these authori-

ties take precedence over the general instructions provided

in this manual.

United States installations

Burner/appliance installations in the United States must comply with the

latest editions of:

•

Installation of Domestic Gas Conversion Burners, ANSI Z21.8.

•

National Fuel Gas Code, ANSI Z223.1/NFPA 54.

•

Standard for the Installation of Oil-Burning Equipment, NFPA 31

•

National Electrical Code, ANSI/NFPA 70.

•

All additional applicable national, state and local codes.

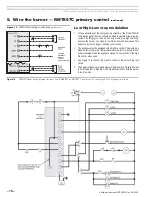

The 702G/O burner, configured for Massachusetts Code

compliance, differs from the standard 702G/O in:

1 Low and high gas pressure switches are added to the gas

train.

2 Jumper JR2 on the primary control is cut, causing the control

to be non-recycling.

Ratings

( With 0.00” w.c. overfire pressure, altitude 2,000 feet max.; see NOTICE

below)

Oil Input

................................................................High fire: 6.0 to 11.2 GPH

................................................................. Low fire: 3.5 to 6.5 GPH

Gas Input

............................................................ High fire: 840 to 1,600 MBH

............................................................... Low fire: 490 to 940 MBH

Fuels

......................................................................No. 1 or No. 2 Fuel oil

....................................................................Natural gas or propane

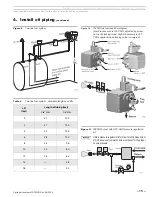

Fuel unit & oil valves:

................Fuel unit,

2-

stage

, 300

psig

(with internal blocking valve)

..................................................................... (2) Oil solenoid valves

Gas train:

(available in straight or angled configuration)

............................(2) Main gas valves & RV-61 or RV-81 regulator

............................................ Butterfly gas valve for input regulation

................ 1" gas train standard; 1¼", 1½" or 2" gas train available

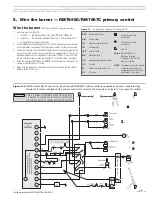

Electrical

Power ............................................................. 120V/60 Hz/1-Phase

Limit circuit input (RM7895C or RM7897C) ..............120 vac/60 hz

Control circuit load (120 vac) .............................................

1.2

amps

Motor ...................................

1/2

hp

, 3450

rpm

, 48-

frame

, “N”

flaNge

..............................

115 / 208-230

vac

/60

hz

/1-

ph

, 8.4 / 3.8-4.2

amps

Oil valve/gas valve power ..........................................

120

vac

/60

hz

Damper motor (with end switch) .........................

h

oNeywell

m436a

Ignition & primary control

.............................Carlin Model 41000 solid state electronic ignitor

Ignition voltage ............................................................. 14,000 volts

Primary control ...............................................Honeywell RM7897C

Agencies

.................................................................................UL Listed (US)

Reduce nozzle/firing rate when required — Maximum burner

capacity is reduced when overfire pressure is positive and for

altitudes above 2,000 feet. See below, and adjust firing rate/

nozzle selection if necessary.

702G/O — Maximum firing rate for

positive overfire pressure and high altitude

Overfire pressure

(Inches w.c.)

Oil – GPH

Gas – MBH

0.00

11.2

1,600

0.10

10.9

1,530

0.20

10.7

1,500

0.30

10.6

1,480

0.40

10.3

1,440

0.50

10.2

1,430

0.60

9.9

1,390

Altitudes:

For altitudes more than 2,000 feet above sea level, reduce the above

capacities an additional 4% per 1,000 feet higher than 2,000 feet

above sea level.

General information