Model 702G/O Advanced gas/oil burners — Instruction manual

Carlin part number MN702GO Rev. 06/23/14

– 24 –

Where appliance instructions differ from this manual, follow the appliance instructions.

Step 4

(firing on gas)

Check gas pilot operation

The Model 702G/O uses a gas pilot for ignition of the gas

main flame. The gas pilot is ignited by the burner electrodes.

1.

After completing Steps 1, 2 and 3 on page 21, move the burner fuel

selector switch to GAS. Set the low-fire switch to low fire.

2.

Make sure the gas line has been completely bled. Then turn the service

switch to ON.

3.

The pilot will usually light the first time once the combustion head as-

sembly and the low-fire air damper have been set by Steps 1 and 2, and

the pilot gas train has been completely purged of air.

4.

The pilot flame is approximately 280 MBH, and is large enough to be

heard when lit. If the pilot fails to light, be sure the gas line has been bled

properly. If it still fails to light, increase the pilot gas pressure to 4 inches

w.c. If the primary control is equipped with a pilot test hold switch, it can

be used to hold the pilot “on” while adjusting pilot gas pressure.

5.

Follow the instructions in the primary control instruction manual to check

flame signal. Make sure the flame signal is steady, and greater than the

required minimum for the UV sensor.

Step 5

(firing on gas)

Set main gas pressure regulator

The butterfly gas valve is factory set to a preliminary setting

of 50% open for low fire, and 100% open for high fire. The

pilot regulator is set for 3.5 inches w.c.

1.

Leave the low-fire switch in low fire.

2.

With the gas pilot operating correctly, and the UV sensor flame signal

above minimum required, the primary control will cycle the burner to

main gas.

3.

Check the flame signal after the pilot has shut down to ensure the signal

8. Adjust the burner using test instruments

(continued)

Smell around the gas train and check all joints with

a soap suds mixture to ensure the gas train and all

components are tight and leak-free. Shut down the

burner and correct any leak immediately. Failure to

comply could result in severe personal injury, death

or substantial property damage.

is still strong with main flame on.

4.

Move the burner fuel selector switch to OFF. The burner will shut down.

5.

Temporarily install two U-tube manometer connections to check gas pres-

sures. Install connections at the inlet pressure tap of the main manual

gas valve and at the downstream pressure tap of the manual gas valve

next to the butterfly valve. (See items 41, page 5.)

6.

The gas pressure at the inlet to the gas train must never exceed

14 inches w.c., either when the burner is off or firing on gas.

7.

Move the burner fuel selector switch to GAS. The burner should start.

8.

With the burner firing in low fire, check the gas pressure at the downstream

manual gas valve tapping. Adjust the main gas pressure regulator if neces-

sary until the gas pressure reads 3.4 inches w.c. as a starting pressure.

9.

Switch the low-fire switch to high fire.

CAUTION

: Be prepared to turn the

burner off immediately if it begins to pulsate as it attempts to move to

high fire.

10.

If the flame pulsates, it is probably too rich. Switch the low-fire switch to

low fire and reduce the gas pressure by adjusting the main gas pressure

regulator. Then return to 9, above.

11.

If the fire is too lean, it will appear small and can even blow out during the

swing to high fire. If it blows out, shut off the burner immediately. Switch

the low-fire switch to low fire and start the burner again. Adjust the main

gas pressure regulator to increase the gas pressure. Return to 9, above.

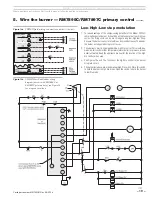

With the burner running in

high fire

, inspect the buttefly valve

shaft slot (Figure 18). The slot must be horizontal. IF NOT, turn

the burner off. Loosen the two hex-head screws securing the

valve linkage arm. With the damper motor linkage arm pulled

up, use a screwdriver to rotate the butterfly valve slot until it is

horizontal. Tighten the two hex head screws while still holding

the damper motor linkage arm up. Return to step 9, above. DO

NOT proceed with combustion adjustment unless the butterfly

valve position has been verified, and corrected if necessary.

12.

With the burner running in

high fire

, adjust the main gas pressure regula-

tor to achieve:

•

Natural gas: 9.6% to 10.0% CO

2

.

•

Propane: 10.7% to 11.2% CO

2

.

•

Measure the CO content. It should be no greater than 100 PPM.

High CO readings may indicate the combustion is on the

wrong side of the CO2 curve. You will know this if a decrease

in gas pressure causes an

increase

in CO2.

13.

The gas pressure may have to be set as low as about 2.0 inches w.c. to as

high as about 4.0 inches w.c., depending on the firing rate of the burner.