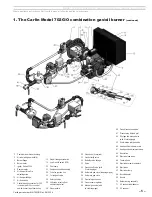

Model 702G/O Advanced gas/oil burners — Instruction manual

Carlin part number MN702GO Rev. 06/23/14

– 10 –

Where appliance instructions differ from this manual, follow the appliance instructions.

Inspect burner and components

•

Check the air tube length. Verify the usable length of the tube UTL will

be long enough (see “Mount burner in appliance”).

•

Visually inspect all burner components and wiring.

•

Verify that wiring is intact and leads are securely connected.

•

Verify that all burner components are in good condition.

Do not install or operate the burner if any component is

damaged or if burner does not comply with other guidelines

of this manual and the appliance manual.

Mount burner in appliance

Welded-flange burners

1.

Verify the bolt pattern on the appliance chamber matches the flange

pattern.

2.

Verify the insertion depth (UTL) matches the depth of the appliance

opening (so the end of the air tube is flush with, or slightly short of, the

inside surface of the combustion chamber).

3.

Place gasket onto boiler front plate.

4.

Slide the end of the air tube into the opening and secure the flange to

the boiler front plate.

Burners with adjustable flanges

1.

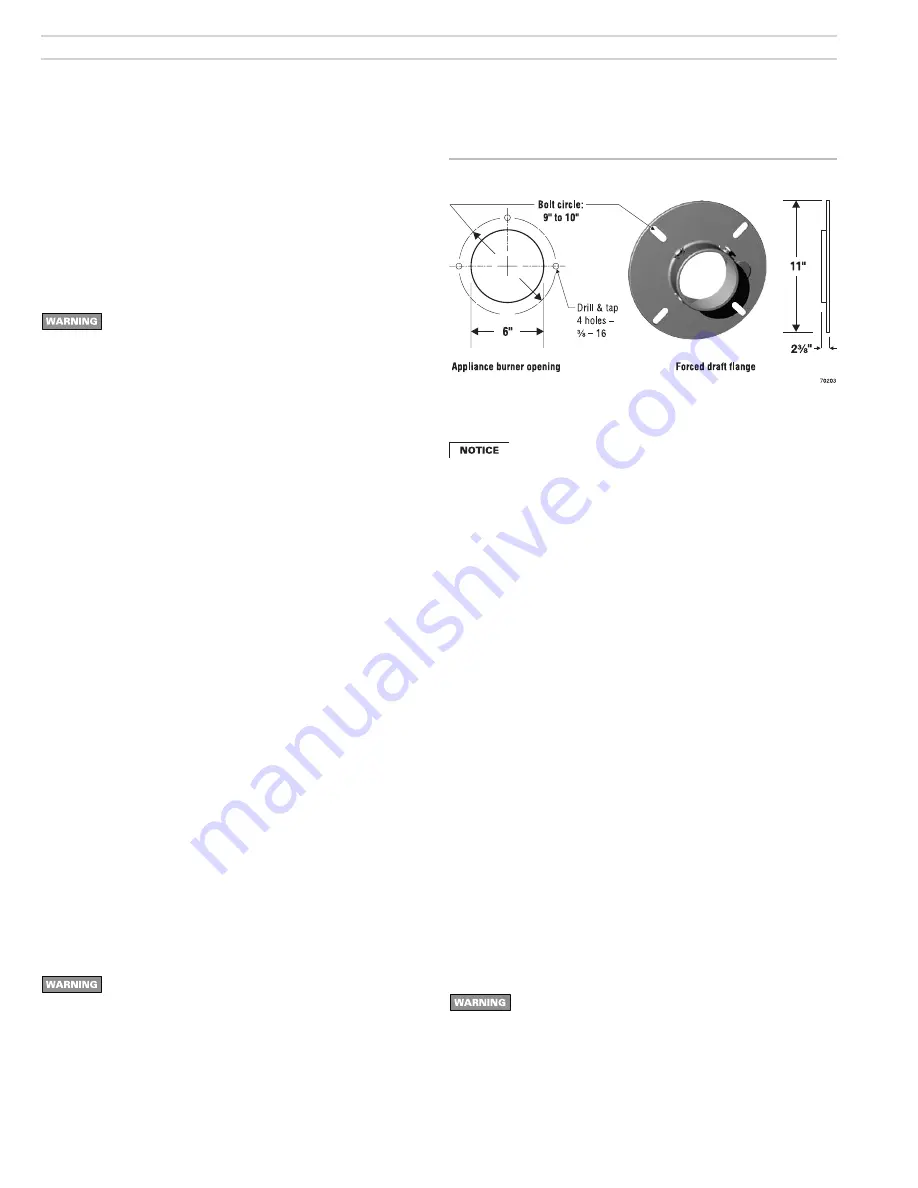

Verify the flange mounting slots will line up with the appliance bolts. (See

Figure 4 for adjustable flange dimensions.)

2.

Place the flange gasket in position on the appliance mounting plate.

3.

Measure the distance from the inside of the combustion chamber to the

outside of the appliance mounting plate. Slide the adjustable flange on

the air tube until it is this distance from the end of the air tube.

4.

Mark this position of the flange on the air tube with a pencil or pen so you

can verify the flange is correctly positioned as you complete the installa-

tion. The end of the air tube must be flush, or almost flush, with the inside

of the combustion chamber wall. (See Figure 3, page 9)

5.

Tighten the flange locking screws finger tight.

6.

Insert the air tube/flange assembly into the appliance opening. (Rotate

the flange if needed to align with the mounting bolts.) Secure the flange

to the appliance front plate.

7.

See the following instructions to install the burner pedestal, needed to

properly support the burner.

A forced draft adjustable flange must be sealed to the air

tube to prevent possible leakage of flue products. Failure

to comply could result in severe personal injury, death or

substantial property damage.

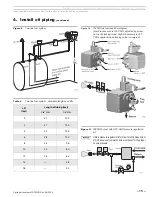

Figure 4

Adjustable flange

2. Prepare site • assemble burner • mount burner

(continued)

Install the burner pedestal

702G/O burners supplied with an adjustable flange are also

supplied with a pedestal for supporting the burner. (The

pedestal is available as an option for a burner equipped

with a welded flange.)

1.

Adjust the pedestal so that the height of the air tube matches the location

of the burner opening.

2.

The pedestal has approximately 3" of adjustment. If the burner opening

is too high for the pedestal to rest on the floor, then construct a base.

Two solid cement blocks, side by side, is recommended. Alternate the

direction as layers are put down.

3.

Place a spirit level on the air tube. Adjust the pedestal so the air tube

slopes down slightly toward the appliance. The slope should be about

2 degrees.

4.

Tighten the pedestal bolt securely.

Install the oil nozzle

1.

Follow the instructions on page 24 to remove the combustion head

assembly.

2.

Install and tighten the nozzle listed in the appliance instruction manual or

the Carlin OEM Spec Guide. If nozzle information is not available, begin

with the nozzle listed on page 4. (You may have to change the nozzle

later if combustion results are not acceptable.)

3.

Slide the flame scanner sight pipe assembly to the rear by loosening the

1/8” Allen screw on the holding base.

4.

Hold the nozzle adapter securely when removing or replacing the nozzle.

Take care not to damage the electrode insulators or to bend the electrodes

in the process.

Inspect the nozzle adapter before replacing the nozzle. If the

threads have been damaged or show score marks, replace

the nozzle line/adapter assembly.