Model 702G/O Advanced gas/oil burners — Instruction manual

Carlin part number MN702GO Rev. 06/23/14

– 4 –

Where appliance instructions differ from this manual, follow the appliance instructions.

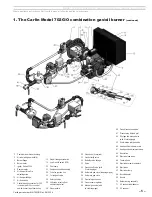

702G/O overview

The Model 702G/O combination gas/oil burner is a low-high-low (step

modulating) burner that utilizes a damper motor to control air (and gas fuel

rate). Fuel is selected using the Gas/oil changeover switch. The burner

operates on either #2 fuel oil or gas (natural or propane).

See the next page for gas train component locations.

Gas mode operation

Ignition for main flame is accomplished by a proved gas pilot of approxi-

mately 280,000 Btuh. Pilot gas is introduced at the main burner flame

retention ring, and is ignited by a Carlin 14,000-volt electronic ignitor

wired to the two electrodes. After the pilot flame is proven, the two main

gas safety valves open. The pilot gas valve closes after a time delay to

allow main flame to establish. Flame is monitored both for pilot flame and

main flame with a UV scanner mounted to the under side of the burner

combustion head assembly. The burner main flame begins at low fire.

If additional input is required, the damper motor opens the gas butterfly

valve and air damper to their high fire positions.

Gas is introduced into the burner through a manifold around the air tube.

The gas then circulates through a set of four orifice spuds into the air

stream, ahead of the retention ring. The spin of the air flow at the retention

ring thoroughly mixes the gas/air before it reaches the combustion zone.

Oil mode operation

Oil ignition is accomplished by the Carlin 14,000-volt electronic ignitor

wired to the two electrodes. The oil flame begins at low fire, with 100

psig

oil pressure at the nozzle. If additional input is needed, the damper mo-

tor opens the air to the high fire position. The damper motor end switch

energizes the 2nd stage oil valve (fuel unit blocking valve) as the damper

approaches its high fire position. This provides 300

psig

pressure to the

oil nozzle for high fire. Flame is monitored by the UV scanner mounted

to the under side of the combustion head assembly.

Firing rate adjustment

•

Firing rate is determined by the oil nozzle. Air flow is matched to the oil

flow for oil firing. Then gas flow is adjusted to match the air flow at low

and high fire rates.

•

See the “Starting and operating” section of this manual for the complete

description of the adjustment process. The following is a brief summary

only.

•

High-fire air is set by adjusting the combustion head position (to control

air flow through and around the retention ring).

•

Low-fire air is then adjusted by fine-tuning the position of the low fire

adjusting screw.

•

Pilot gas flow is set for a smooth light-off. Then gas inputs are adjusted

for good combustion at low and high-fire air settings.

1. The Carlin Model 702G/O combination gas/oil burner

702G/O oil nozzles

Use the selections below when the heating equipment

manufacturer’s specific nozzle selection data is not available,

either in the equipment manual or the Carlin OEM Spec

Guide. Follow all instructions provided with the appliance.

Nozzle specifications

•

Preferred

—

Hago 45° SS

•

Alternate

—

Hago 45° P or Monarch 45° PLP

Nozzle ratings

Full input (high fire) occurs at 300 psig nozzle pressure. Since nozzles

are rated at 100 psig, the actual flow at 300 psig is approximately 73%

higher than the rated nozzle capacity. See the table below for nozzle

rating selections.

Table 1

702G/O oil nozzles

Oil Nozzle Sizing

Equipment

Input rating

GPH

Recommended

nozzle rating

GPH

Low fire

input

(100 psig)

High fire

input

(300 psig)

6.00

3.50

3.50

6.00

6.50

3.75

3.75

6.50

6.90

4.00

4.00

6.90

7.80

4.50

4.50

7.80

8.70

5.00

5.00

8.70

9.50

5.50

5.50

9.50

10.40

6.00

6.00

10.40

11.20

6.50

6.50

11.20

1. For a packaged appliance application on which the burner has been tested, use the noz-

zle given in the appliance manufacturer's instructions or supplement for the best

results.

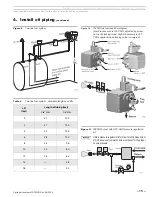

Gas pressure requirements

The 702G/O burner requires 3.4" w.c. minimum pressure at the butterfly

valve during high fire. Select a gas train that has a pressure drop no

more than the available pressure at the gas train inlet minus the 3.4"

needed at the butterfly valve. See page 13 for gas train pressure drop

information. The burner is equipped with a 1" gas train unless a larger

gas train is ordered.

Example: A boiler has an input rating of 1,300,000 Btuh. Gas pressure

available at the gas train entrance is 6.0" w.c. Subtract 3.4” from the

available 6.0" w.c. The gas train pressure drop must be 2.6” or less. A 1"

gas train has a pressure drop of 3.3" w.c., and cannot be used. Select a

1¼" RV-61 regulator gas train, which has a pressure drop of 0.87" w.c.