2

| CAV 4.1 Operation Manual

Specifications/Compliances

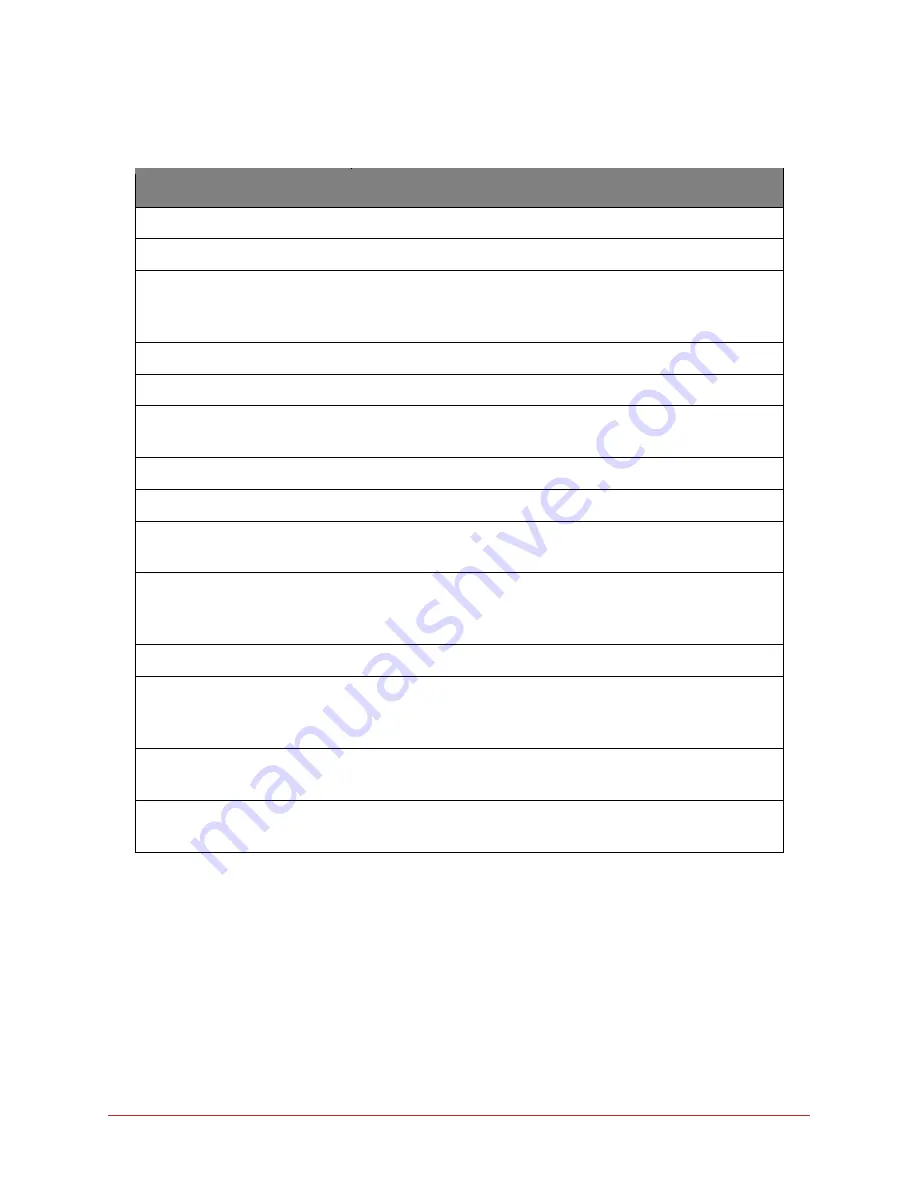

Table 1 — Specifications and Compliances

Specifications

Details

Model

CAV 4.1 Benchtop Kinematic Viscometer

Methodology

ASTM D445/D446, ISO 3104/3105, IP 71

Applications

Formulated oil analysis, hydraulic oil analysis, additive

analysis, marine fuel testing, base stock analysis, light and

heavy fuel testing, waxes/paraffin, crude oil testing, glycols

Dimensions

(W × D × H)

36 cm × 66 cm × 72 cm (14.15 in × 26 in × 28.5 in)

Weight

63 kg (140 lb)

Temperature range &

Accuracy

40 °C to +100 °C (± 0.01 °C); Up to 150 °C (± 0.03 °C)

Down to 20 °C (± 0.03 °C) with integrated TE bath cooler

Maximum throughput

24 tests per hour

Automated sample capacity

28 positions (2 × 14 positions)

Minimum sample/solvent

volume required

8 mL sample/15 mL solvent per test

*as little as 3mL with fast run tubes

Viscosity range

0.5 mm²/s to 10,000 mm

2

/s in 100-fold increments

(depending on viscometer tubes selected).

Fast run tubes are also available

Timing resolution

0.01 seconds (timing accuracy to ± 0.001 seconds)

Power requirements

100 V

AC

, 50/60 Hz, 1200 W

115 V

AC

, 50/60 Hz, 1200 W

230 V

AC

, 50/60 Hz, 1200 W

Operating conditions

15 °C to 30 °C, 10% to 75% relative humidity (non-

condensing), Installation Category II, Pollution Degree 2

Compliance

CE Mark: EMC Directive (2004/108/EC); Low Voltage

Directive (2006/95/EC); ROHS

Notes/Cautions/Warnings

Notes, caution, and warnings are used in the manual to call an operator’s attention to important details

prior to performing a procedure or step. Read and follow these important instructions. Failure to

observe these instructions may void warranties, compromise operator safety, and/or result in damage

to the CAV 4.1.