Synergy Technician's Software Reference Page 1

In addition to the

Maintenance Screen

, there is also a

Diagnostic Screen

and

Calibrate Screen

that are used

to manually operate specific components of the Synergy.

There are additional settings that may require fine-tuning

is a component fails and requires changing. Your software

version may be out of date with this manual. To confirm

the software version while the software is running press the

Synergy Logo

on the

Navigation bar

and the version will

appear. There may be other features in your system that

you do not find listed here. It is advised that these features

be ignored and treated as non-operational.

Calibrate Screen

When the

Calibrate Screen

is loaded, the technician

needs to press

Begin Calibration

to enable the calibration

sequences. This will prevent automated processes from

disrupting the calibration process. When the technician is

complete with Calibration, press

Stop Calibration

. The

technician will not be able to exit the

Calibration Screen

until they press

Stop Calibration

.

Every Calibration sequence will feature specific instruc

-

tions for the calibration. A

Finish Calibration

button or

Cancel Calibration

appears in the bottom right to exit

calibration before the end of the sequence. Some calibra-

tions are multi-step processes that will feature a

Next Step

button next to the

Finish/Cancel

button.

●

Test Valve Mappings

: Check if the Valves are

operating as intended by automatically cycling a

specific target valve every 5 seconds.

●

Calibrate Source Tanks

: Calibrate the scales for

the Source Tanks. It involves placing an empty

container on the scale and gradually filling it.

●

Calibrate Nozzles

: Carriages assembled at Brown

Manufacturing are tested for a target performance

standard. If it is suspected that the system is not

spraying correctly, use this sequence to confirm the

calibration. It is not advised to change the values

presented in this screen without a Brown Manufac-

turing Technician available.

●

Calibrate Projector

: This sequence calibrates the

size and placement of the load zone on the belt.

If the load zone had drifted or it is not displaying

correctly, go through these steps to correct any

miscalibration in the projector.

●

Calibrate Belts

: This sequence allows for calibrat

-

ing the lengths of each belt, as well as pretreater

settings relating to firefly operation.

Diagnostic Screen

The Diagnostic Screen allows for direct control of every

sub-component of the system, this includes all pumps,

valves, sensors, motors, control boards, and more. The

Diagnostic Screen features navigation buttons to quickly

jump to where a particular form of diagnostic begins. This

screen is most useful in diagnosing bad parts, and confirm

-

ing the operation of misbehaving parts. Page Navigation

can be used by pressing on the arrows at the bottom of the

screen.

●

Plumbing

: Jumps to the first page, where control

and feedback of plumbing begins.

●

Motors

: Jumps to the first page of motors diagnos

-

tic, where motors can be controlled directly.

●

Software

: Jumps to the first page of Software di

-

agnostic, where the software can be controlled and

monitored directly.

●

Last Page

: Jumps to the last page of diagnostics.

●

Stop All

: Stops all current plumbing and motor

operations. Uses a hard stop on every motor, and

resets all internal state machines.

Plumbing Control

The plumbing control screen includes

Pumps

,

Valves

and

Boards

. There is also a

Manual Override

button which

temporarily disables mixing. The

Stop Board

buttons

disable the pump and valves associated with that board.

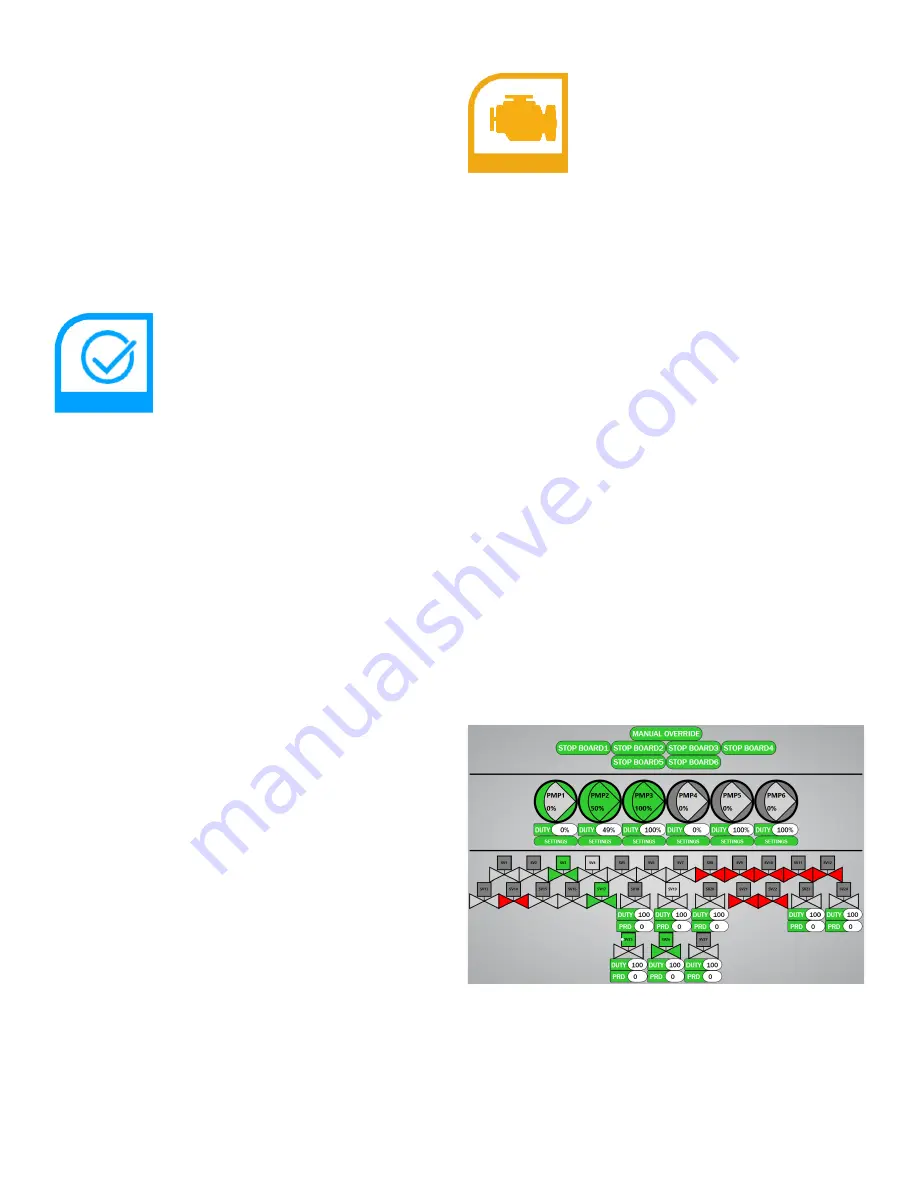

Image 1

Image 1: Plumbing Control Screen

The

Pumps

use the same symbol found in the

Plumbing

Schematic

and are labeled

PMPx

, with the inside of the

triangle representing feedback from the pump, and the

outside of the triangle representing control to the pump. If

the area is

gray

then the state has not changed since startup,

if the area is

white

then the state is currently inactive, if the