Maintenance...

Messages

5-190

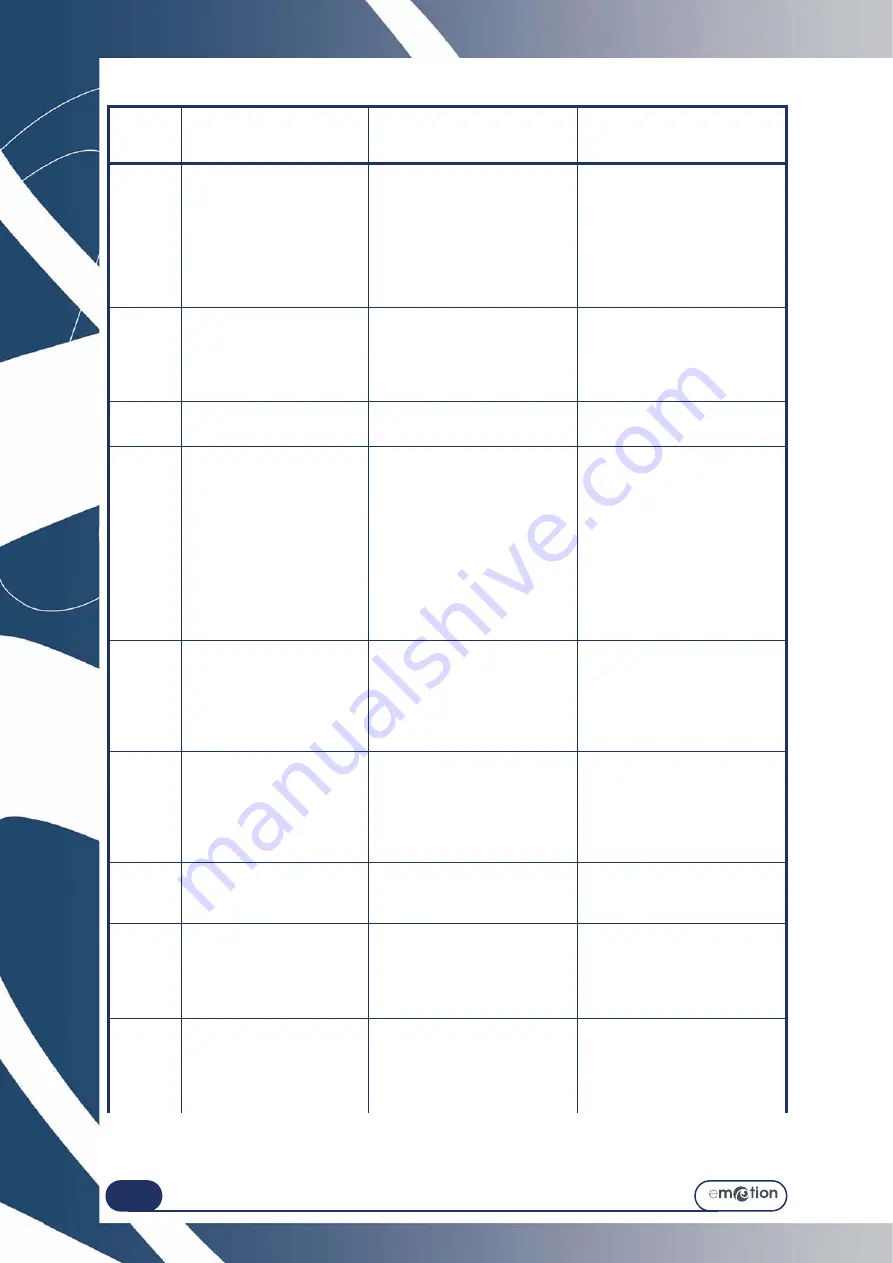

0x25

Incompatible edger

configuration.

Safety-bevel to be defined

not allowed.

The job you have loaded has the

parameter Safety-bevel to be

defined.

In the personalisation menus,

you have excluded this

parameter.

Therefore the edger cannot

accept this job.

Confirm the message.

If you wish to load this job

nonetheless, change the

personalisation of the pull-down

menus.

Select the Safety-bevel to be

defined parameter.

Load the job again.

0x26

Retouch impossible on

drilled or grooved lens.

You wish to undertake a retouch

on a lens which has been drilled

or grooved. This operation is

impossible on a lens with these

finishes.

Carry out the lens size

adjustment procedure. Fit a new

lens and enter a negative

oversize value.

0x2B

Wrong job received.

Problems of communication with

the server have been detected.

Load another job number

0x30

Do you want to save the

new personalisation?

At least one of the parameters

of the menus personalisation

has changed. The machine

requests confirmation of this

modification.

Confirm: the new

personalisation is registered.

No confirmation: the new

personalisation is not registered.

The previous personalisation is

retained.

Cancel: you return to the

personalisation screen for the

menu-button concerned.

Reselect the elements you wish

to display.

0x34

Groove too near front.

The distance between the front

face of the lens and the external

edge of the groove is less than

0.2 mm.

Confirm the message.

Select Manual Groove sub-

finishing.

Visualise the position of the

groove on the control screen.

Reposition the groove.

0x35

Groove too far back.

The distance between the rear

face of the lens and the internal

edge of the groove is less than

0.2 mm.

Confirm the message.

Select Manual Groove sub-

finishing.

Visualise the position of the

groove on the control screen.

Reposition the groove.

0x100

Requested job does not

exist.

You have called up a job number

but the corresponding job is not

on the server.

Call up another number.

0x101

No response from server

within time limit.

You have tried to load a job but

the edger has not received a

signal from the server.

Check that:

- The server is switched on.

- The OMA cord is correctly

connected to both terminals.

Then load the job again.

0x102

The server is switched off.

The OMA cord is disconnected.

OR

The server is switched off.

Check that:

- The server is switched on.

- The OMA cord is correctly

connected to both terminals.

Then load the job again.

#

Message

Condition(s) for

display

Action(s)

Содержание emotion

Страница 1: ...Operation manual...

Страница 3: ......

Страница 9: ...Table of contents...

Страница 10: ...REVISION FOLLOW UP Revision 01 Page New Modified Item New document...

Страница 11: ...3 10...

Страница 12: ...1 INSTALLATION...

Страница 13: ...1 12 UNPACKING THE MACHINE 1 2 3 4 5 8 9 Keep the case the small carton and the hose near the machine 6 7...

Страница 15: ...Installation Unpacking the machine 1 14...

Страница 17: ...Installation Removing the shipping rails 1 16...

Страница 23: ...Installation Water connections 1 22...

Страница 25: ...Installation Electrical connections 1 24 1 3 2...

Страница 28: ...2 SAFETY PRECAUTIONS...

Страница 29: ...2 28...

Страница 31: ...Safety precautions Safety 2 30...

Страница 33: ...2 32 Safety precautions Recommendations...

Страница 34: ...3 USING YOUR EDGER...

Страница 35: ...3 34...

Страница 41: ...3 40...

Страница 45: ...Using your Edger General principles of use 3 44 Pin 1 2 3 5 Blocker head Blocker arm 4...

Страница 47: ...Using your Edger General principles of use 3 46 3 2 4 USUAL PROCEDURE EDGING Enter the Edging tab...

Страница 51: ...Using your Edger General principles of use 3 50...

Страница 75: ...Using your Edger Special cases 3 74...

Страница 87: ...Using your Edger Special cases 3 86...

Страница 94: ...4 CONFIGURATION...

Страница 95: ...4 94...

Страница 102: ...Configuration Configuration of finishing parameters default values 4 101...

Страница 107: ...Configuration Correction of frame and lens values 4 106...

Страница 112: ...5 MAINTENANCE...

Страница 113: ...5 112...

Страница 117: ...Maintenance Visualising the components 5 116...

Страница 119: ...Maintenance Task list 5 118...

Страница 121: ...Maintenance Maintenance of the touch screen unit 5 120 Illustration 5 1 Scanform...

Страница 124: ...Maintenance Maintenance of the Scanform unit 5 123...

Страница 125: ...Maintenance Maintenance of the Scanform unit 5 124 Illustration 5 1 Centering blocking system...

Страница 131: ...Maintenance Regular maintenance of the edger 5 130...

Страница 135: ...Maintenance Regular maintenance of the edger 5 134...

Страница 147: ...Maintenance Regular maintenance of the edger 5 146...

Страница 149: ...Maintenance Handling the covers 5 148...

Страница 151: ...Maintenance Preventive maintenance 5 150...

Страница 156: ...Maintenance Adjustments 5 155...

Страница 157: ...Maintenance Adjustments 5 156 Screen 5 4 Feeling adjustment...

Страница 159: ...Maintenance Adjustments 5 158 Screen 5 5 Adjusting the sizes Screen 1...

Страница 163: ...Maintenance Adjustments 5 162 Screen 5 6 Adjustment of the flush of the mill bit...

Страница 165: ...Maintenance Adjustments 5 164 Screen 5 7 Adjustment of the touch screen...

Страница 167: ...Maintenance Adjustments 5 166 Screen 5 8 Example of a setting values display screen...

Страница 169: ...Maintenance Adjustments 5 168...

Страница 173: ...Maintenance Consulting the statistics 5 172...

Страница 196: ...6 TESTS...

Страница 197: ...6 196...

Страница 203: ...Tests Operating principle 6 202...

Страница 204: ...7 TECHNICAL SPECIFICATIONS...

Страница 205: ...7 212...

Страница 209: ...Technical specifications Technical specifications 7 216...

Страница 210: ...2 rue Roger Bonnet 27340 PONT DE L ARCHE FRANCE Tel 33 02 32 98 91 32 Fax 33 02 35 02 02 94...