VDL (E3.1) 06/2020

Page 122/206

13.3

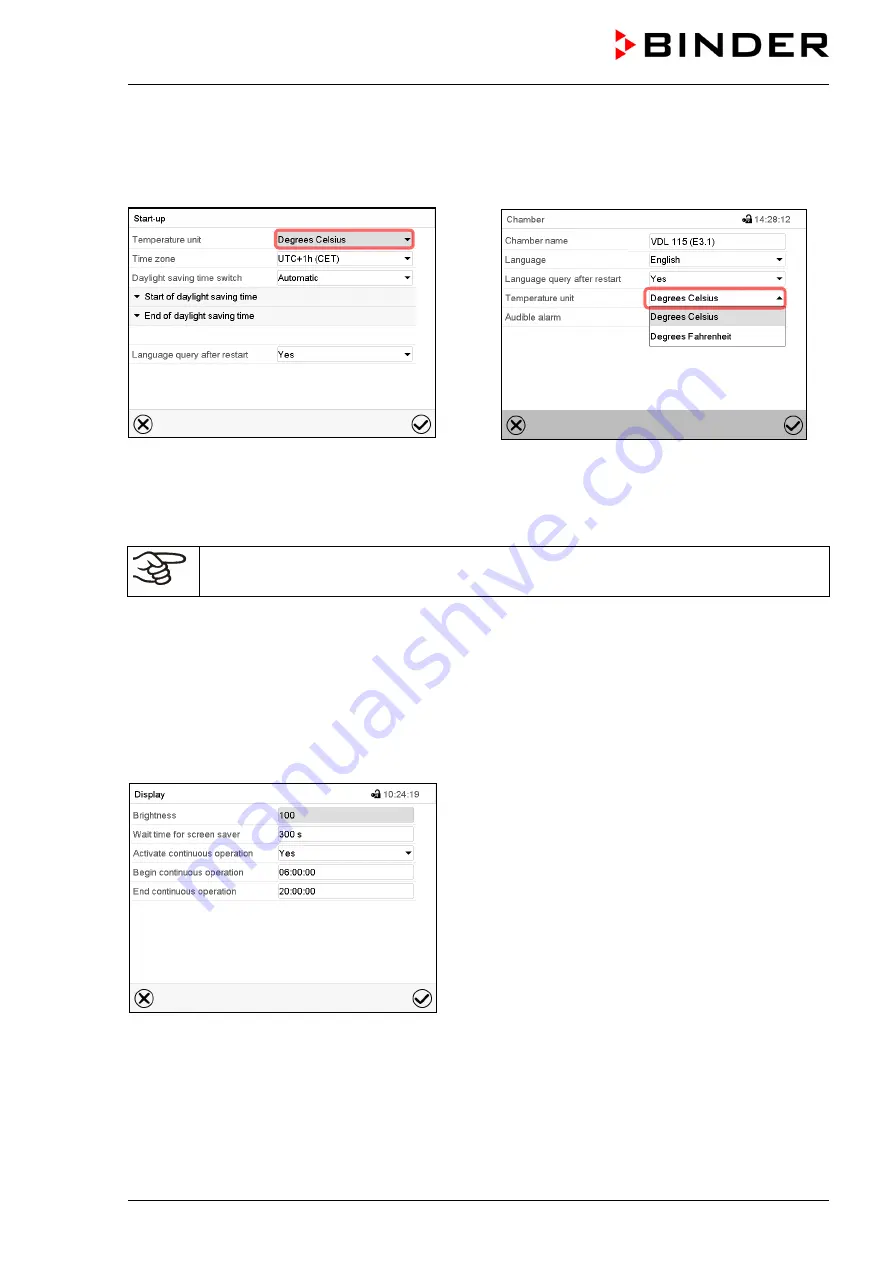

Selecting the temperature unit

Following start-up of the chamber:

Or later:

Path:

Main menu > Settings > Chamber

Select the desired temperature unit and press

the

Confirm

icon.

Change of the temperature unit between °C and °F.

If the unit is changed, all values are converted accordingly

C = degree Celsius

F= degree Fahrenheit

0 °C = 31°F

100 °C = 212°F

Conversion:

[value in °F] = [value in °C]

∗

1,8 + 32

13.4

Display configuration

13.4.1 Adapting the display parameters

This function serves to configure parameters like display brightness and operating times.

Path:

Main menu > Settings > Display > Display

“Display” submenu.

Содержание vdl 115

Страница 192: ...VDL E3 1 06 2020 Page 192 206 28 6 Dimensions 28 6 1 VDL 23 Dimensions in mm ...

Страница 193: ...VDL E3 1 06 2020 Page 193 206 28 6 2 VDL 56 Dimensions in mm ...

Страница 194: ...VDL E3 1 06 2020 Page 194 206 28 6 3 VDL 115 Dimensions in mm ...

Страница 197: ...VDL E3 1 06 2020 Page 197 206 30 Certificates and declarations of conformity 30 1 EU Declaration of Conformity ...

Страница 198: ...VDL E3 1 06 2020 Page 198 206 ...

Страница 199: ...VDL E3 1 06 2020 Page 199 206 ...

Страница 200: ...VDL E3 1 06 2020 Page 200 206 31 Product registration ...

Страница 207: ......