page 43

page 43

page 43

page 43

page 43

160B&C TM

800-00140

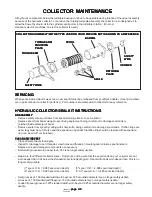

COLLECTOR MAINTENANCE

COLLECTOR MAINTENANCE

COLLECTOR MAINTENANCE

COLLECTOR MAINTENANCE

COLLECTOR MAINTENANCE

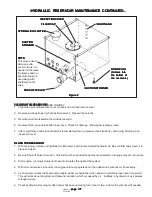

All hydraulic components below the turntable bearing continue to be operable during rotation of the upper assembly

because of the hydraulic collector. Located on the rotating turntable assembly, the collector is so designed as to

allow the flow of hydraulic oil to the cylinders at all points in the turntable rotation. (On most

stationary electric machines, an electric collector is used.)

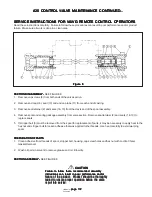

COLLECTOR SHOWN MAY NOT BE TYPE USED ON YOUR MACHINE BUT IS SHOWN AS A REFERENCE.

COLLECTOR SHOWN MAY NOT BE TYPE USED ON YOUR MACHINE BUT IS SHOWN AS A REFERENCE.

COLLECTOR SHOWN MAY NOT BE TYPE USED ON YOUR MACHINE BUT IS SHOWN AS A REFERENCE.

COLLECTOR SHOWN MAY NOT BE TYPE USED ON YOUR MACHINE BUT IS SHOWN AS A REFERENCE.

COLLECTOR SHOWN MAY NOT BE TYPE USED ON YOUR MACHINE BUT IS SHOWN AS A REFERENCE.

SAFETY WIRE

SAFETY WIRE

SAFETY WIRE

SAFETY WIRE

SAFETY WIRE

TORQUE ARM

TORQUE ARM

TORQUE ARM

TORQUE ARM

TORQUE ARM

TORQUE ARM

TORQUE ARM

TORQUE ARM

TORQUE ARM

TORQUE ARM

MOUNTING

MOUNTING

MOUNTING

MOUNTING

MOUNTING

PLATE

PLATE

PLATE

PLATE

PLATE

SEALS

SEALS

SEALS

SEALS

SEALS

SAFETY

SAFETY

SAFETY

SAFETY

SAFETY

WIRE

WIRE

WIRE

WIRE

WIRE

RETAINING

RETAINING

RETAINING

RETAINING

RETAINING

PLATE

PLATE

PLATE

PLATE

PLATE

SCREWS

SCREWS

SCREWS

SCREWS

SCREWS

BARREL

BARREL

BARREL

BARREL

BARREL

SPOOL

SPOOL

SPOOL

SPOOL

SPOOL

SERVICING

SERVICING

SERVICING

SERVICING

SERVICING

When seals inside collector wear out, a new seal kit must be purchased from your Barko dealer. (Seal kit numbers

are in parts manual on collector parts list.) Port numbers are stamped into collector for easy reference.

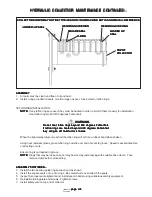

HYDRAULIC COLLECTOR SEAL KIT INSTRUCTIONS

HYDRAULIC COLLECTOR SEAL KIT INSTRUCTIONS

HYDRAULIC COLLECTOR SEAL KIT INSTRUCTIONS

HYDRAULIC COLLECTOR SEAL KIT INSTRUCTIONS

HYDRAULIC COLLECTOR SEAL KIT INSTRUCTIONS

DISASSEMBLY

DISASSEMBLY

DISASSEMBLY

DISASSEMBLY

DISASSEMBLY

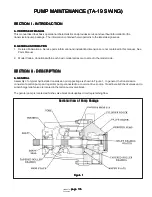

- Remove safety wire and screws from spool retaining plate on top of collector.

- Remove spool from barrel using proper driving equipment, being careful not to damage seal lands or

polished inside diameter of barrel.

- Remove seals from spool by cutting with sharp knife, being careful not to damage spool lands. If teflon rings are

used, they must be cut off also and the expansion ring under the teflon ring should be replaced (the expansion

ring can be cut off or stretched).

CLEAN AND INSPECT

CLEAN AND INSPECT

CLEAN AND INSPECT

CLEAN AND INSPECT

CLEAN AND INSPECT

- Clean all components thoroughly.

- Inspect for damage to port threads, screw holes and threads, hole elongation, broken spool lands,etc..

Replace or repair damaged components as necessary.

- Barrel with grooves worn deeper than .007 is no longer safely usable.

- Below are four different collector sizes. Find yours, and be sure that the spool lands on your collector are not

worn deeper than .004 below the standard spool land depth given. Spool with lands worn deeper than .004 is no

longer safely usable.

(7" spool O.D. = 6.985 spool land depth) (5" spool O.D. = 4.985 spool land depth)

(6" spool O.D. = 5.985 spool land depth) (3-1/2" spool O.D. = 3.485 spool land depth)

- Seal grooves of .160 standard width worn beyond .185 at outside diameter are no longer safely usable.

- Grooves of .130 standard width beyond .150 at outside diameter are no longer safely usable.

- Loaded lip seal grooves of .275 standard width worn beyond .325 at outside diameter are no longer safely

usable.