page 38

page 38

page 38

page 38

page 38

160B&C TM

800-00140

HYRAULIC OIL FILTER MAINTENANCE

HYRAULIC OIL FILTER MAINTENANCE

HYRAULIC OIL FILTER MAINTENANCE

HYRAULIC OIL FILTER MAINTENANCE

HYRAULIC OIL FILTER MAINTENANCE

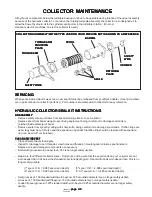

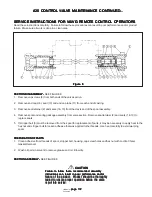

Figure 1

Figure 1

Figure 1

Figure 1

Figure 1

THE " SUCTION" FILTER

THE " SUCTION" FILTER

THE " SUCTION" FILTER

THE " SUCTION" FILTER

THE " SUCTION" FILTER

(SEE FIGURE 1)

(SEE FIGURE 1)

(SEE FIGURE 1)

(SEE FIGURE 1)

(SEE FIGURE 1)

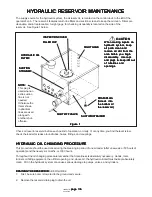

This filter is mounted near the shrouding enclosure. The suction filter (565-00113) contains a replaceable filter element

which simply unscrews from the filter head. See the Parts Manual for complete parts breakdowns.

FILTER HEAD

FILTER HEAD

FILTER HEAD

FILTER HEAD

FILTER HEAD

GASKET

GASKET

GASKET

GASKET

GASKET

FILTER

FILTER

FILTER

FILTER

FILTER

ELEMENT

ELEMENT

ELEMENT

ELEMENT

ELEMENT

FILTER HOUSING

FILTER HOUSING

FILTER HOUSING

FILTER HOUSING

FILTER HOUSING

(WELDED TO TOP

(WELDED TO TOP

(WELDED TO TOP

(WELDED TO TOP

(WELDED TO TOP

PLATE

PLATE

PLATE

PLATE

PLATE

OF HYDRAULIC OIL

OF HYDRAULIC OIL

OF HYDRAULIC OIL

OF HYDRAULIC OIL

OF HYDRAULIC OIL

RESERVOIR)

RESERVOIR)

RESERVOIR)

RESERVOIR)

RESERVOIR)

TOP PLATE OF

TOP PLATE OF

TOP PLATE OF

TOP PLATE OF

TOP PLATE OF

HYDRUALIC OIL

HYDRUALIC OIL

HYDRUALIC OIL

HYDRUALIC OIL

HYDRUALIC OIL

RESERVOIR

RESERVOIR

RESERVOIR

RESERVOIR

RESERVOIR

FILTER HEAD AND

FILTER HEAD AND

FILTER HEAD AND

FILTER HEAD AND

FILTER HEAD AND

BYPASS

BYPASS

BYPASS

BYPASS

BYPASS

BOLTS

BOLTS

BOLTS

BOLTS

BOLTS

O-RING

O-RING

O-RING

O-RING

O-RING

FILTER

FILTER

FILTER

FILTER

FILTER

ELEMENT

ELEMENT

ELEMENT

ELEMENT

ELEMENT

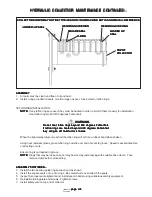

Figure 2

Figure 2

Figure 2

Figure 2

Figure 2

THE " RETURN" FILTER

THE " RETURN" FILTER

THE " RETURN" FILTER

THE " RETURN" FILTER

THE " RETURN" FILTER

(SEE FIGURE 2)

(SEE FIGURE 2)

(SEE FIGURE 2)

(SEE FIGURE 2)

(SEE FIGURE 2)

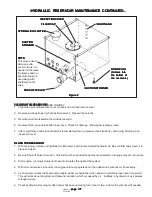

The Return Filter (565-00116, on machines with s/n's of

18676 & higher) is welded into the hydraulic oil reservoir.

The filter head must be unbolted, twisted, and lifted off to

reveal the filter element which can then be removed and

replaced.

On a new machine the filter elements must be changed after the first 50 hours of operating time

and then every 400 hours after that.

On a new machine the filter elements must be changed after the first 50 hours of operating time

and then every 400 hours after that.

ELEMENT REPLACEMENT PROCEDURE

ELEMENT REPLACEMENT PROCEDURE

ELEMENT REPLACEMENT PROCEDURE

ELEMENT REPLACEMENT PROCEDURE

ELEMENT REPLACEMENT PROCEDURE

1.

Remove old element by unscrewing it from filter head.

2.

Remove used gasket from groove in filter head.

3.

Take new gasket from inside new element and install in groove in filter

head.

4.

Apply oil to new gasket.

5.

Screw element on by hand until tight, to seat gasket in groove.

6.

Loosen element.

7.

Retighten element until it contacts gasket, then tighten 1/2 to 3/4 of a turn.

8.

Check for leaks after start-up.

NOTE:

NOTE:

NOTE:

NOTE:

NOTE: On machines with s/n's lower than 18676, the Return Filter is the

same as the Suction Filter. On machines with s/n's of 18676 and

higher, the Return Filter is as follows.