page 134

page 134

page 134

page 134

page 134

160B&C TM

800-00140

GRAPPLE SERVICE & INSTALLATION CONTINUED...

GRAPPLE SERVICE & INSTALLATION CONTINUED...

GRAPPLE SERVICE & INSTALLATION CONTINUED...

GRAPPLE SERVICE & INSTALLATION CONTINUED...

GRAPPLE SERVICE & INSTALLATION CONTINUED...

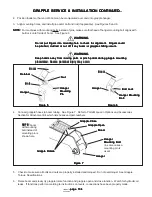

4. Connect grapple hoses to boom tubing. See Figure 7. Refer to Parts Manual in Options and Accessories

Section for Attachment Kit, which lists hoses and part numbers.

Hanger

Hanger

Hanger

Hanger

Hanger

Mounting Bolt

Mounting Bolt

Mounting Bolt

Mounting Bolt

Mounting Bolt

(in some cases a

mounting pin is

used)

Hanger

Hanger

Hanger

Hanger

Hanger

Boom

Boom

Boom

Boom

Boom

Grapple Open

Grapple Open

Grapple Open

Grapple Open

Grapple Open

Grapple Close

Grapple Close

Grapple Close

Grapple Close

Grapple Close

Boom

Boom

Boom

Boom

Boom

Hanger

Hanger

Hanger

Hanger

Hanger

Bolt Lock

Bolt Lock

Bolt Lock

Bolt Lock

Bolt Lock

Hanger Mounting

Hanger Mounting

Hanger Mounting

Hanger Mounting

Hanger Mounting

Bolt

Bolt

Bolt

Bolt

Bolt

Figure 5

Figure 5

Figure 5

Figure 5

Figure 5

Figure 6

Figure 6

Figure 6

Figure 6

Figure 6

Nut

Nut

Nut

Nut

Nut

Hanger

Hanger

Hanger

Hanger

Hanger

Mounting

Mounting

Mounting

Mounting

Mounting

Pin

Pin

Pin

Pin

Pin

Bolt

Bolt

Bolt

Bolt

Bolt

Retainer

Retainer

Retainer

Retainer

Retainer

Boom

Boom

Boom

Boom

Boom

Hanger

Hanger

Hanger

Hanger

Hanger

Grapple Rotate

Grapple Rotate

Grapple Rotate

Grapple Rotate

Grapple Rotate

NOTE:

NOTE:

NOTE:

NOTE:

NOTE: boom

with mounting

bolt instead of

mounting pin is

shown here.

Figure 7

Figure 7

Figure 7

Figure 7

Figure 7

5. Check to make sure all bolts and nuts are properly installed and torqued. Do not overtorque! See Grapple

Torque Specifications.

6. Raise boom and slowly try grapple rotate function and grapple open and close function. Watch for hydraulic oil

leaks. If functions perform according to instructions on levers, connections have been properly made.

2. Position loader so that end of boom can be manipulated over and onto grapple hanger.

3. Align mounting holes, and install pin and/or bolt and nut (if applicable). See Figures 5 and 6.

NOTE:

NOTE:

NOTE:

NOTE:

NOTE: For machines with mounting bolts instead of pins, make sure that head of hanger mounting bolt aligns with

bolt lock on left side of boom. See Figure 6.

WARNING

WARNING

WARNING

WARNING

WARNING

Do not put fingers into mounting hole to check for alignment. Fingers could

Do not put fingers into mounting hole to check for alignment. Fingers could

Do not put fingers into mounting hole to check for alignment. Fingers could

Do not put fingers into mounting hole to check for alignment. Fingers could

Do not put fingers into mounting hole to check for alignment. Fingers could

be pinched, crushed or cut off if any boom or grapple shifting occurs.

be pinched, crushed or cut off if any boom or grapple shifting occurs.

be pinched, crushed or cut off if any boom or grapple shifting occurs.

be pinched, crushed or cut off if any boom or grapple shifting occurs.

be pinched, crushed or cut off if any boom or grapple shifting occurs.

WARNING

WARNING

WARNING

WARNING

WARNING

Keep hands away from moving parts or pinch points during grapple mounting

Keep hands away from moving parts or pinch points during grapple mounting

Keep hands away from moving parts or pinch points during grapple mounting

Keep hands away from moving parts or pinch points during grapple mounting

Keep hands away from moving parts or pinch points during grapple mounting

procedures. Severe personal injury may occur.

procedures. Severe personal injury may occur.

procedures. Severe personal injury may occur.

procedures. Severe personal injury may occur.

procedures. Severe personal injury may occur.