page 104

page 104

page 104

page 104

page 104

160B&C TM

800-00140

MAIN DISASSEMBLY -

MAIN DISASSEMBLY -

MAIN DISASSEMBLY -

MAIN DISASSEMBLY -

MAIN DISASSEMBLY -

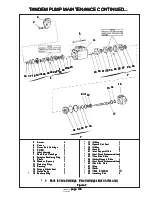

Use Figure 2 as a reference for all procedures

Use Figure 2 as a reference for all procedures

Use Figure 2 as a reference for all procedures

Use Figure 2 as a reference for all procedures

Use Figure 2 as a reference for all procedures

1. Remove two pipe plugs (13) in cover (6), and drain the oil from the unit.

2. Loosen and remove the four shoulder bolts (14) and eight grade 8 bolts (12) from cover (6).

3. Remove cover (6) from hub (1G).

4. Remove o-ring (5) from the counterbore in cover (6) and discard.

5. Remove thrust washer (11) from the counterbore in carrier housing (3A).

6. Remove input gear (9) from mesh with planet gears (3F).

CAUTION

CAUTION

CAUTION

CAUTION

CAUTION

Safety glasses should be worn during this step.

Safety glasses should be worn during this step.

Safety glasses should be worn during this step.

Safety glasses should be worn during this step.

Safety glasses should be worn during this step.

7. Using a punch, remove retaining ring (20) from the groove around the inside of input gear (9) and discard.

Minimum

Minimum

Minimum

Minimum

Minimum

1.02 inches

1.02 inches

1.02 inches

1.02 inches

1.02 inches

Maximum

Maximum

Maximum

Maximum

Maximum

.65 inches

.65 inches

.65 inches

.65 inches

.65 inches

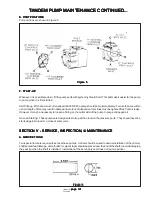

Figure 1

Figure 1

Figure 1

Figure 1

Figure 1

TIGHTENING AND TORQUEING BOLTS CONTINUED...

TIGHTENING AND TORQUEING BOLTS CONTINUED...

TIGHTENING AND TORQUEING BOLTS CONTINUED...

TIGHTENING AND TORQUEING BOLTS CONTINUED...

TIGHTENING AND TORQUEING BOLTS CONTINUED...

Use Figure 1 as a reference.

1. Tighten (but do not torque) bolt “A” until snug.

2. Go to the opposite side of the bolt circle and tighten bolt “B”

until equally snug.

3. Continue around the bolt circle and tighten the remaining

bolts.

4. Now use a torque wrench to apply the specified torque to

bolt “A”.

5. Continue around the bolt circle and apply an equal torque to

the remaining bolts.

FILLING WITH OIL AND OIL CHANGE

FILLING WITH OIL AND OIL CHANGE

FILLING WITH OIL AND OIL CHANGE

FILLING WITH OIL AND OIL CHANGE

FILLING WITH OIL AND OIL CHANGE

INTERVALS

INTERVALS

INTERVALS

INTERVALS

INTERVALS

For normal applications, use EP90 gear fluid.

Fill until oil is as high as top of cluster bearings - see illustration

at right.

Check oil level daily.

Initial oil change should be done after 50 hours of operating time.

Change every 400 hours after that.

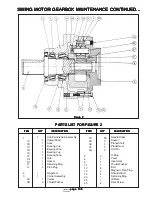

SWING MOTOR GEARBOX MAINTENANCE CONTINUED...

SWING MOTOR GEARBOX MAINTENANCE CONTINUED...

SWING MOTOR GEARBOX MAINTENANCE CONTINUED...

SWING MOTOR GEARBOX MAINTENANCE CONTINUED...

SWING MOTOR GEARBOX MAINTENANCE CONTINUED...